Contents

- 1 Set-Up

- 2 Pay Rates

- 3 Quote-Groups

- 4 Preference Settings

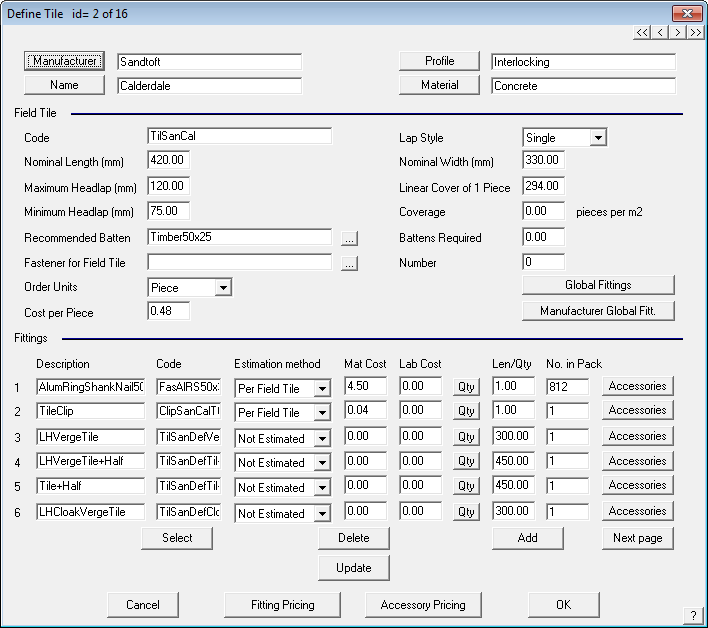

- 5 Tiles

- 6 Shingles

- 7 Shakes

- 8 Metal Panels

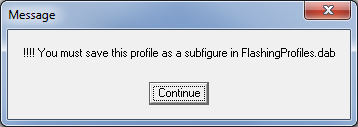

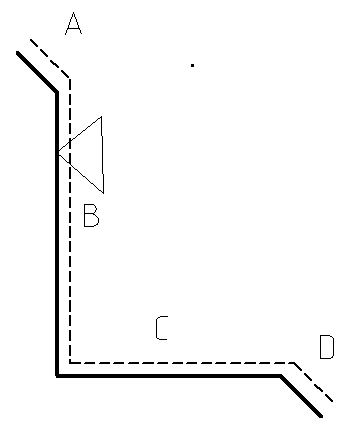

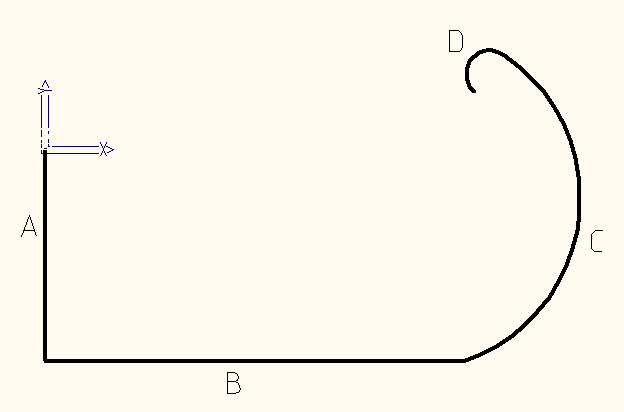

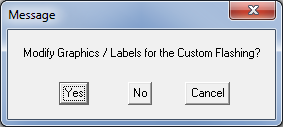

- 9 Flashings

- 10 Fasteners

- 11 Insulation

- 12 Tile-Colours

- 13 Metal-Colours

- 14 Tiles+

- 15 Flat-Sheet

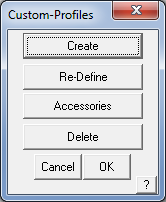

- 16 Custom-Profiles

- 17 Membrane

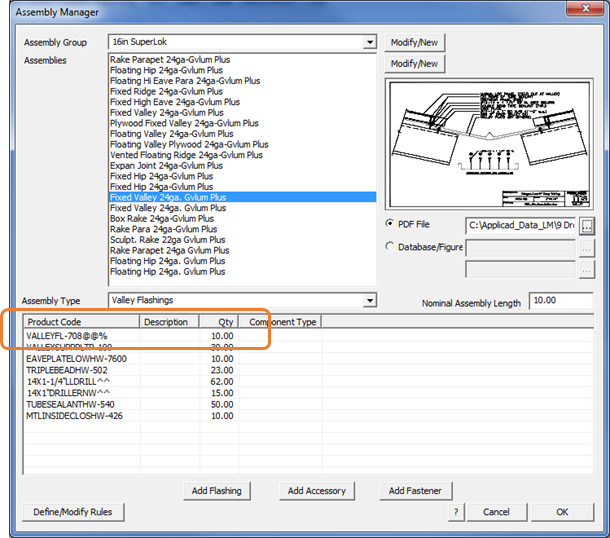

- 18 Flashing Assemblies

- 19 Fixtures

- 20 Downpipes

- 21 Extra-Items

- 22 Area-Names

- 23 People

- 24 Curving-Charges

Set-Up

When Roof Wizard software is installed, basic generic materials and settings are provided to get you going. However, with software in 148 countries, it is impossible to have everything set exactly as each and every user wants and needs. You will need to make many additions and some adjustments. You will be using the files located in the C:\AppliCad\Roof Wizard\User folder or in a shared network folder mapped as a virtual drive. Generally they are a series of *CSV (Comma Seprated Values format files). Being CSV files you may use an editor such as Wordpad.exe or Notepad.exe to edit them, however, because the format is compatible with Microsoft’s Excel program and other spreadsheet software, you may prefer to edit them there. The huge advantage of editing in a spreadsheet program is the ability to make global changes to things like prices etc.

!!!However – keep in mind that the commands provided under the Set-Up options described below are designed to help you edit these files efficiently from within the Roof Wizard software and ensure that they are correct. If you are not competent or confident with using the spreadsheet program, stick with editing the files from within the Roof Wizard software. You can then rely on the result working properly when you’re finished editing the information.

The files in C:\AppliCad\Roof Wizard\Programs are best considered as a backup if you mess with the working copies in the ..\User folder and need to revert to something that works. If a file is required by the software and it doesn’t exist in the ..\User folder, for whatever reason (on first use or if it was deleted), the software will find the backup in the \Programs folder, use that and then create a copy in the ..\User folder. This provides a level of security should things go awry.

Note: For anyone updating from an older version during installation, the software will find the original version of your setup files and leave them there. If the format of a file has changed, for example material definitions for tiles, then the installation software will automatically convert the old format to the new format of that file.

In most cases there will be many additional items and adjustments to the software settings. This is usual and should not be seen as a chore – you do it once, check that it is correct and then you use it over and over every single day.

With the correct material and labour files set up, extracting the complete set of documents for the quoting, order, supply and installation of a job like this metal roof in Port Elizabeth, South Africa, takes about an hour.

Easy!

Your Company Details

The company details are the name and details that you want to appear automatically on your reports. You can define multiple business names in Roof Wizard for that situaiton where you have different branches or business units getting their estimating done by a centralised location.

The first step is to define the details of your company in the software, so that the reports print with your details on them. To define your company details select Set-Up > Your Company Details from the Pulldown menu. This will bring up the following dialog box.

From here you can type in the details of your company. When the details have been filled in click [Add], then [OK] and your company details will be saved permanently.

Name The name of your company.

Address The address of your company.

Phone The phone number of your company.

Fax The fax number of your company (if applicable).

Note 1 For additional information if required, such as company by-line or could also be used for second email address.

Note 2 For additional information if required – maybe the company’s web site address.

Business No. You could use this for your ABN (Australian Business Number), VAT No. or any other detail you wish to use. It doesn’t have to be a business number to be used on a report or header. Refer to the section dealing with defining templates to get a handle on how this information is used bythe software to generate reports.

Pay Rates

Set up > Pay Rates takes you to the Labour setup commands – specifically,

Tilers’ pay rates – fixed Allows you to setup fixed tile rates.

Tilers’ pay rates – variable Allows you to setup variable tile rates – with increments for storey and pitch interval.

Tile waste factors Allows you to setup tile waste factors.

Metal pay rates – fixed Allows you to setup fixed metal rates.

Metal pay rates – variable Allows you to setup variable metal rates – with increments for storey and pitch interval.

Curved metal pay rates Allows you to setup curved metal installation rates.

Nett pay rates Allows you to setup nett pay rates ie nett cost/m².

Quote Groups Allows you to setup Quote Groups.

Wall cladding pay rates Allows you to setup Wall cladding installation rates.

Tilers’ Pay Rates

Tilers’ Pay Rates – Fixed

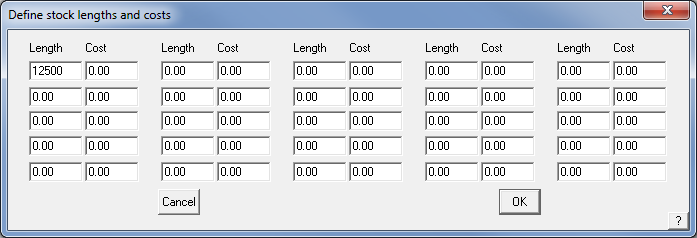

This command displays the Roof Costing-Rates dialog box allowing you to set or change various quote rates and job cost rates associated with the estimate on a per square basis or per unit length. There is one rate regardless of pitch of the roof or storey number. The items are described below:

Hip cover length This value determines the number of hip tiles required. It is independent of the tile you selected.

Note that it is not used if you have supplied a hip tile length when you defined the tile using Set-Up > Tile.

Underlay/Sarking roll size This value determines the number of rolls of underlay.

Cartage per 100 tiles This value determines the total delivery cost. (Refer note below if you do not wish to have this displayed in the Supply and Install/Supply Only summaries.)

Underlay/Sarking quote rate This is the rate to quote underlay/sarking.

Fall protection quote This is the rate to quote fall protection.

Default no of units This is the default number of housing units for this job.

Batten 50×25 quote This is the rate to quote 50×25 battens.

Batten 50×38 quote This is the rate to quote 50×38 battens.

Batten 50×50 quote This is the rate to quote 50×50 battens.

Batten 75×50 quote This is the rate to quote 75×50 battens.

Batten User quote This is the rate to quote the user defined batten.

Ridge cover length This value determines the number of ridge tiles required. It is independent of the tile you selected.

Note that it is not used if you have supplied a ridge tile length when you defined the tile using Material > Tiles.

Batten length This is the length of battens per m2 of roof. It is used if you perform the estimate using the area method.

Underlay/Sarking cost rate This is the cost of the underlay/sarking.

Fall protection cost This is the cost of the fall protection.

2nd storey excess An extra value for second storey work.

Installers percentage The extra percentage to apply to the installers pay.

Batten 50×25 quote This is the cost of 50×25 battens.

Batten 50×38 quote This is the cost of 50×38 battens.

Batten 50×50 quote This is the cost of 50×50 battens.

Batten 75×50 quote This is the cost of 75×50 battens.

Batten User quote This is the cost of the user defined batten.

Waste per course The number of tiles you want to add per course if using the coursing method.

Waste – area method The number of extra pieces you want based on the total length of hips and valleys.

Sealant The rate per metre to add sealant to the trim. You define the finish of the ridges, gables and valleys etc as “Seal” to get a sealant value added to the Reporting dialog box.

Flexible pointing The rate per metre for flexible pointing.

![]()

Note: The cartage per 100 tiles variable described above will not appear in the Supply and Install dialog if the value is set to 0.

If a value is included, then it will appear and the value determined by the number of tiles ordered. If a value is set, then it will only appear in the material list summary if you have estimated for tile.

This will be added to the material list specifically for tile cartage, even if a value is also set for delivery under Areas – refer to Set-Up > Areas (where you can set delivery to not show). If you have both set, then both values will be displayed in the Supply and Install/Supply Only summaries. Typically you will have one or the other, but not both.

Tilers’ Pay Rates – Variable

Tilers’ Pay Rates – Variable

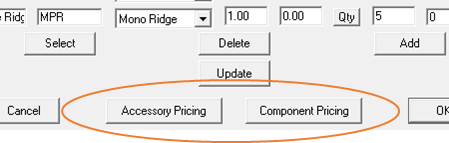

This command lets you define tile installer pay schedules based on storey, line-item and user defined pitch interval.

This Pay Rate is applied to the Tiles+ database when setup as described below and Tiles+ is selected as the database to use in System Preferences. You may define as many Tile-Pay rates as you need – for example, union or non-union rates; or sub-contractor A and sub-contractor B rates. Just remember, the more rates you set up the more you have to maintain if rates change, as they inevitably do.

Name This is the name by which you select this pay rate in future.

Roof Unit The basis on which the costs are applied and the multiplier.

Storey This is the storey to which these values relate. You can have up to 10 storeys for the one pay rate.

Pitch intervals These values reflect those you set with the Intervals button at the foot of the dialog box. For each pitch interval value, you get a column of numbers associated with a line item. To edit a line item, highlight that column by clicking the pitch interval label.

Roof / sqm (sqFt) This is the installers rate to lay tiles on the roof.

…. The rest of the line items relate to hip, valley, gable and barge finishes you select under Cover > Select-tile.

Select This allows you to select an existing pay rate schedule.

Delete This allows you to delete an existing pay rate schedule.

Add This allows you to add a new pay rate schedule.

Update This allows you to update an existing pay rate schedule.

Auto-Fill Interval Automatically fills the table with the loading for each pitch interval.

Auto-Fill Storey Automatically fills the table with the loading for each storey.

Once the pricing table has the appropriate rates for each job function completely filled in, and don’t forget to do each storey, the file is saved away in the system using the “Add” button. Standard pricing files are stored within the software structure however user-defined pricing files are stored in a <filename>.DPT file format. In our example we created a labour pay rate file called “Interlocking Concrete Tiles” so this will be saved as InterlockingConcreteTiles.DPT.

Once the pricing table has the appropriate rates for each job function completely filled in, and don’t forget to do each storey, the file is saved away in the system using the “Add” button. Standard pricing files are stored within the software structure however user-defined pricing files are stored in a <filename>.DPT file format. In our example we created a labour pay rate file called “Interlocking Concrete Tiles” so this will be saved as InterlockingConcreteTiles.DPT.

The <filename>.DPT file is saved in a text file which allows you to make changes in an external program such as Notepad or Wordpad, or indeed, a spreadsheet program such as Excel. This is useful if you have major changes to pricing across the board and changing the values in columns is a whole lot easier in Excel if you know how. For the rest of us, open the pricing file in AppliCad (Costing > Tile-Pay) and do it long hand, one item at a time. Once complete don’t forget to select “Update” and the changes will be saved.

Interval Labels

Customers utilising the GRIM output feature of AppliCad to link the estimation process to downstream systems have often had to create duplicate mappings of labour rates due to the output of variable labour rates in the Roof Wizard software. Outputs such as Ridge (1, 22.5) where the 1 specifies the storey and 22.5 specifies the pitch have had to create multiple mappings for each pitch gradient in 0.1 degree increments. In 8.2, we have provided the ability for each pitch interval to be given as a label (e.g. A, B, C as can be seen in the attached image) with the output therefore being Ridge (1,A), or Ridge (1,B) etc. This greatly reduced the number of mappings required, thus reducing the workload for our users and speeding up the interface between systems.

Labour Item Descriptions

Labour Setup (Tiles Database)

NOTE: The following description for setting up labour rates applies to Roof Wizard V11.0 and up.

If you’re not using Tiles+, DO NOT use LabourFile.DAT (as described below for Tiles+) for the regular Tiles database. Things go awry and it is difficult to undo.

The standard labour items are described in the file TileLabourMenus.DAT.

The file looks like this when viewed in Notepad:

Roof name, Hip, then Ridge main name followed by 2 additional options (these are added to the price of the main Ridge/Hip line); then Valley main name and again 2 more pricing options, additional to the Valley price. Gable has 3 additional line items, not 2 like the rest. Underlay, Apron, Batten, Counter Batten, Fall Protection and Downpipes follow.

Note: All items must stay in their relative positions in the list.

Once setup as described above, the pay rate structure looks like this (the rates displayed below are random):

Once defined, set a name, then select [Add] to create a new labour rate, or [Update] to change the rates. Once added, these values are saved to the file TLabour5.csv in the ..\User folder.

Further rates are added to this list as you define them based on your settings for Storey Interval and and Pitch Interval. If you hit the [Update] button, you must next select [OK] to quit so that the file is saved as you exit.

At the bottom of this CSV file are the item labels as defined for your labour rates:

For the Tiles database, select your pre-defined pay rate here:

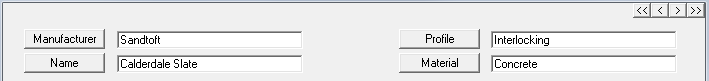

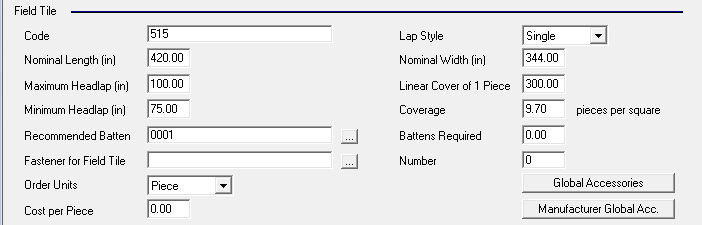

The selected tile details dialog for Tiles data file.

![]() Note: Should the pay rate be changed for any reason after you have selected it, then you must reselect the rate. Indeed, this applies to any database of materials or Reporting – if it is changed, you must re-select it and re-calculate the labour and materials costing.

Note: Should the pay rate be changed for any reason after you have selected it, then you must reselect the rate. Indeed, this applies to any database of materials or Reporting – if it is changed, you must re-select it and re-calculate the labour and materials costing.

When you calculate the tile quantities, either by area or coursing, the rates flow through to the Supply and Install summary of costs.

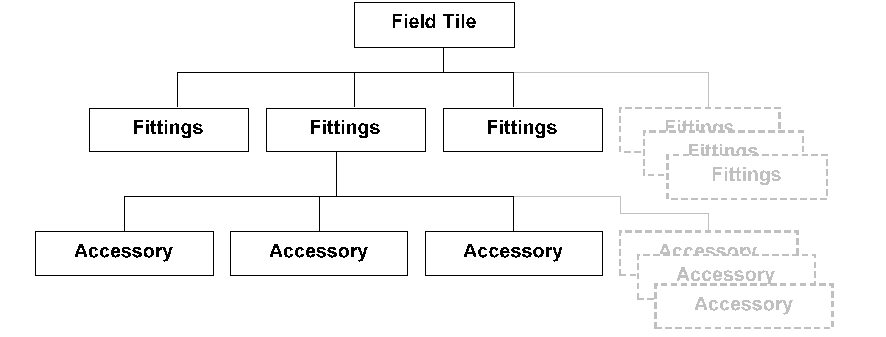

Labour Setup (Tiles+ Database)

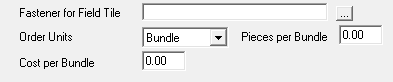

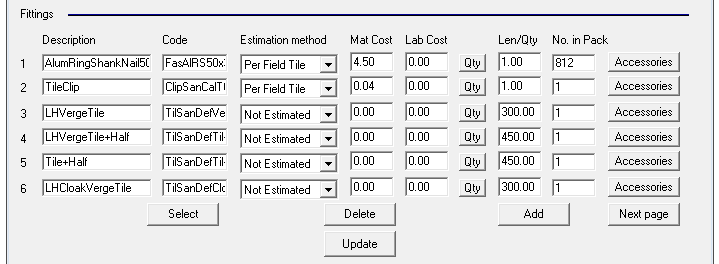

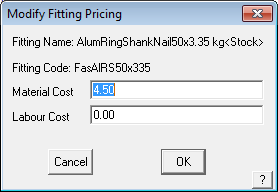

Available when using the Tiles+ database setup, is the ability to define the Labour item descriptions. These definitions are stored in a text file called LabourFile.dat and may be created or edited in a text editor such as Notepad or Wordpad.

The quick way to create the user defined group description file is to copy the file “LabourFile.TMP” to “LabourFile.DAT” in Windows Explorer, and then make any modifications using a Windows-based text editor such as NotePad or WordPad. Only attempt to edit this file if you are proficient in the use of the editor program. To return to standard groupings, the user must remove the file “LabourFile.DAT” so that the “LabourFile.TMP” in the user directory is found instead. You might also open LabourFile.TMP in the editor and use File | Save-As to create the LabourFile.DAT with your new descriptions and charges.

This will handle every permutation of Reporting for your tile item installation options.

The format of the LabourFile.dat:

#Tile Labour File #Line above must remain in file for it to be located by software #Format 0=Header, 1=Main Cost, 2=Add Cost > Group Description > Reporting Calculation Method 1=Area, 2=Len |Group - see below #1 = Field Tiles, 2 = Ridge, 3 = Hip, 4 = Valley, 5 = Verge, 6 = Eaves, 7 = Abutments, 8 = Aprons, 9 = Box Gutters, 10 = Battens, 11 = Counter Battens, 12 = Insulation, 13 = Sarking/Underlay, 14 = Fall Protection, 15 = Downpipes, 20 = Extras #Last option defines whether default is to include in Pricing or not 0=No, 1=Yes 0|AREA|0|1|0 1|Field Tiles|1|1|1 2|Extra Over for Nailing Coverings Twice|1|1|0 2|Extra Over for Clipping Coverings in Lieu of Nails|1|1|0 2|Extra Over for Clipping Coverings plus Nailing|1|1|0 0|RIDGE|0|2|0 1|Mortar Bed & Mechanically Fix All End|2|2|1 1|Two Ridge Dry Ridge System|2|2|0 2|Dentil Slips|2|2|0 2|Extra Over Mechanically Fix All Ridge|2|2|0 0|HIP|0|3|0 1|Mortar Bed & Mechanically Fix All End|2|3|1 1|Two Hip Dry Hip System|2|3|0 2|Dentil Slips|2|3|0 2|Extra Over Mechanically Fix All Hip|2|3|0 2|Arris/Bonnett Hip|2|3|0 2|Mitred Hip|2|3|0……………….etc

Below is a screen shot of the file we created for the demonstrating the function. Notice the header of the file shows the order in which the information must be input. Once setup, you have total control over the descriptions you use for each labour item. This includes whether the labour relates to Field tile, ridge or hip etc, the description and the cost per area or per length.

The “LabourFile.DAT” file has the following format, as outlined in the header of the file:

# = Comment Line A|B|C|D|E = Data Line, where: A 0 = Header Line 1 = Main Cost 2 = Additional Cost B Line Item Description C 1 = Item to be priced by Area 2 = Item to be priced by Length D 1 = Field Tile Category 2 = Ridge Tile Category 3 = and so on, see documentation E 0 = Do Not include in pricing calcs by default 1 = Include in pricing calcs by default.

Screen captured from the LabourFile.dat being edited in Windows Notepad

The pay rate is selected when the tile is selected to cover the roof under the Cover > Tiles command.

Apart from the labour costs that can be associated with any particular accessory or component under the Set-Up > Tiles+ setup, it is expected that most users will want to set up labour options based on the Set-Up > Set Up Pay Rates > Tilers’ pay rates – variable (not Tile-Rates) menu which permits the user to associate costs to tile profiles and have these costs cross-referenced with the relative pitch and storey of any given roof plane it is joined to. You may define as many labour files as you need for different profiles, different sub-contractors or different geographic areas – whatever works for your business. Refer to the Reference Manual section on Cover > Tile-Pay for more details on setting up the pay rates.

Once the labour rate is defined, the labour pay scale for the installation of a job is set when the tile profile is selected under the Cover > Tiles command.

The Labour Setup for Tiles+ is very extensive and allows the user to operate in one of 2 modes; either using the standard grouping descriptions as released with the software, or to create user defined grouping descriptions to suit your circumstances. The grouping descriptions are set up in a file you create that must be called “LabourFile.DAT” as described above.

The existence of this file in the user directory of the software determines whether the user wishes to use user-defined grouping descriptions in the Set-Up > Set Up Pay Rates > Tilers’ pay rates – variable menu as opposed to the standard grouping descriptions as released with the software. If it does not exist (because you didn’t define new grouping descriptions) the file provided with the software by the name of “LabourFile.TMP” is used instead, resulting in the descriptions shown below left. The difference is most easily explained by reviewing the 2 resultant dialog boxes.

For the Tiles+ database select it here:

The selected tile details dialog for Tiles+ data file.

Below are examples of the result of setting up your own defined labour rates.

Click the down arrow for a drop down list of available pay scales that you have defined.

![]() Note: Should the pay rate be changed for any reason after you have selected it, then you must reselect the rate. Indeed, this applies to any database of materials or Reporting – if it is changed, you must re-select it and re-calculate the costing.

Note: Should the pay rate be changed for any reason after you have selected it, then you must reselect the rate. Indeed, this applies to any database of materials or Reporting – if it is changed, you must re-select it and re-calculate the costing.

Remember: After creating a new labour file, test it on a simple job to ensure the descriptions are transposed correctly. If it works correctly, then you are ready to use it on real jobs. This is a good tip whenever you change or update a data file, whether a labour or material data file.

Each dialog box demonstrates the value for each respective field for a pitch interval as well as a given storey. Thus, various values can be entered to allow for different pitch and storey rates often charged by sub-contractors working on a job. The “Auto-Fill Interval” and “Auto-Fill Storey” buttons assist in the filling in of values across the dialog by allowing the user to specify a percentage increase from the first interval / storey and to automatically fill the other fields in the dialog box with the modified values.

Tile-Waste

Tile-Waste

This command displays the Tile-Waste dialog box allowing you to set or change the wastage factors for different tile items.

The tile wastage values are calculated in the following sequence:

The nett number of field tiles is first calculated,

Then the number of extra pieces per course is added,

Then the extra number of field pieces per length of hips and valleys is added (field pieces per metre or per foot of hip and valley),

Then the percentage waste of field pieces is added,

Then the total number of field pieces rounded to give the final number.

Each waste value is applied in turn. If you do not want a particular waste factor to be applied then set the value to zero.

The first option – Extra Field Pieces (per course) is a number or decimal fraction, of a tile to add at the end of each course line to account for waste as a result of typical job variables such as breakages. The more course lines, the more field pieces that are added to the total tile count.

Extra Field Pieces (per length of hip and valley) is applied as a result of the total length of hip and valley combined and expressed as pieces or decimal fraction of pieces, per metre (or foot) of hip and valley. This is typically used to account for extra tiles that may be required as a result of breakages during cutting of tiles to fit at hips and valleys.

The more cuts there are, often the more breakages there are. No account is made for the re-use of the off-cut, as is sometimes possible with metal tiles.

If the off-cut is reused as a matter of course, then this needs to be taken into account and the number reduced. Experiment with different values until you get the correct result based on your experience.

All other fields are individual values for each category of tile piece. Waste % takes the total number calculated based on the course lines and adds the specified percentage and then rounds up to the nearest value as specified. A value of zero does not round up.

Multiple configurations of tile wastage and rounding of elements can be specified and saved into various configuration files. These files can now be linked to each tile record, thus allowing improved streamlining of waste and rounding calculation without requiring the estimator to remember to modfiy these values. Select [Save-As] to save the tile waste file and select [Load] to load a previously defined set of values.

When you click [OK], the values are saved. These values are applied to the tile calculations when the Reporting > Supply+Install is selected. A summary of the tile waste calculations is then displayed when you select Tile-Waste from the Supply+Install or Supply-Only dialog box.

Metal Pay Rates

Metal Pay Rates – Fixed

This command displays the Roofing Labour rates dialog which allows you to set installation rates for different categories of roofing items on a per square or per unit length basis. There is one rate regardless of pitch of the roof or storey number. The following table describes the rates:

Labour Rate |

Description |

Straight roofing per m2 |

The rate to install straight sheeting on the roof (or verandah) |

Insulation per m2 |

The rate to lay the insulation |

Ridges/hips per m |

The rate to install the ridges and hips |

Valley per m |

The rate to install valley flashing |

Fascia only per m |

The rate to install fascia flashing only |

Gutter only per m |

The rate to install gutter only |

Fascia barge per m |

The rate to install fascia on a barge |

Fascia and gutter per m |

The rate to install fascia and gutter together |

Barge per m |

The rate to install barge flashing |

Apron per m |

The rate to install apron flashing |

Batten per m |

The rate to install battens |

Each Downpipe |

The amount to install each downpipe |

Each chimney |

The rate to cater for each chimney |

Labor markup % |

The percentage the total labour cost will be marked up in the final costing |

Labour quantities |

This is either “NETT values” or “GROSS values”. Nett values are the geometric values of the roof. Gross values are the quantities of materials you order. Setting the method here will effect the quantity you see in the Reporting dialog boxes later. They only apply to metal roofing and metal flashing quantities for all methods of labour calculation – fixed and variable. |

Siding per sqm |

The rate to install siding per square metre |

Wall top per m |

The rate to install wall top flashing |

External corner per m |

The rate to install external corner flashing |

Internal corner per m |

The rate to install Internal corner flashing |

Door head per m |

The rate to install door head flashing |

Door edge per m |

The rate to install door edge flashing |

Box gutter per m |

The rate to install box gutter |

Curved roofing per m2 |

The rate to install the curved sheeting on the roof (or verandah) |

Each curved sheet |

The amount to add for each curved sheet |

Per curved apron |

The amount to add for each curved apron (bullnose verandahs) |

Per curved barge |

The amount to add for each curved barge (bullnose verandahs) |

Per curved hip |

The amount to add for each curved hip (bullnose verandahs) |

Per curved valley |

The amount to add for each curved valley (bullnose verandahs) |

Curved apron per m |

The rate to install curved apron (bullnose verandah) |

Curved barge per m |

The rate to install curved barge (bullnose verandah) |

Curved hip per m |

The rate to install curved hip (bullnose verandah) |

Curved valley per m |

The rate to install curved valley (bullnose verandah) |

Roof removal per m2 |

The rate for roof removal |

Gutter removal per m |

The rate for gutter removal |

Material markup % |

The rate to markup the material costs for the final quote |

Wall base per m |

The rate to install wall base flashing |

Window sill per m |

The rate to install window sill flashing |

Window head per m |

The rate to install window head flashing |

Window edge per m Wall Batten per m |

The rate to install window edge flashing The rate to install wall battens per metre |

After you make a change and click [OK], the changes are saved in rates.bin for use in all future jobs.

If you click the Pitch Allowance button the Pitch Allowances dialog box is displayed.

Here, you set the pitch ranges as well as the rate to apply for planes in that range. When you click Set Range, you can change the number of ranges. The maximum number of ranges you can have is 10.

These values are used in the labour charge calculation under Reporting > Supply+Install. Each plane in the model is tested for its pitch and area, and based on the roof pitch, the above table is used to derive a pitch allowance. The individual pitch allowances are added together to derive the total pitch allowance.

![]() Note: If the Set Up > Set up Pay Rates > Metal Pay Rates Fixed option of “Labour quantities” is set to “Use NETT values,” the labour rates for fascia and gutter are combined under Supply & Install > Labour SubTotal into a single line item of “Fascia and gutter m.”

Note: If the Set Up > Set up Pay Rates > Metal Pay Rates Fixed option of “Labour quantities” is set to “Use NETT values,” the labour rates for fascia and gutter are combined under Supply & Install > Labour SubTotal into a single line item of “Fascia and gutter m.”

If the “Labour quantities” is set to “Use GROSS values,” the labour rates for fascia and gutter are kept separate under Supply & Install > Labour SubTotal as “Fascia only m” and “Gutter only m.”

Metal Pay Rates – Variable

This command displays the Installer Pay Rates for Metal roofing box allowing you to set or change various labour rates associated with the installation of metal roofing. You select a pay-schedule for a job on the Cover > Select-metal dialog box. The maximum number of different labour rate tables is 50.

Name This is the name of this pay schedule.

Storey This is the storey to which the following rates apply. A schedule can have up to 10 storeys.

Pitch Intervals These are the pitch intervals you want to set for the job. You set them by clicking the Intervals button at the foot of the dialog. To edit a column of values you need to click on the interval value.

Line items For each line item you need to enter the rate per unit area or length for that line item. For roof removal and gutter removal only the first rate is actually read when the Reporting is performed.

Select This button lists up the existing schedules. You then select the one you want for editing. After selecting a schedule, the Update button appears letting you update the schedule.

Delete This button lets you delete the currently selected schedule.

Add This button lets you add the current schedule (schedules must have unique names).

Update Updates the currently selected table with changes.

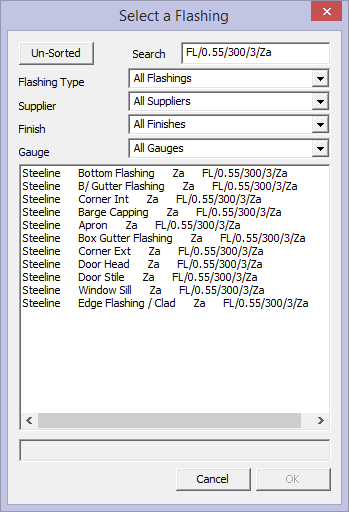

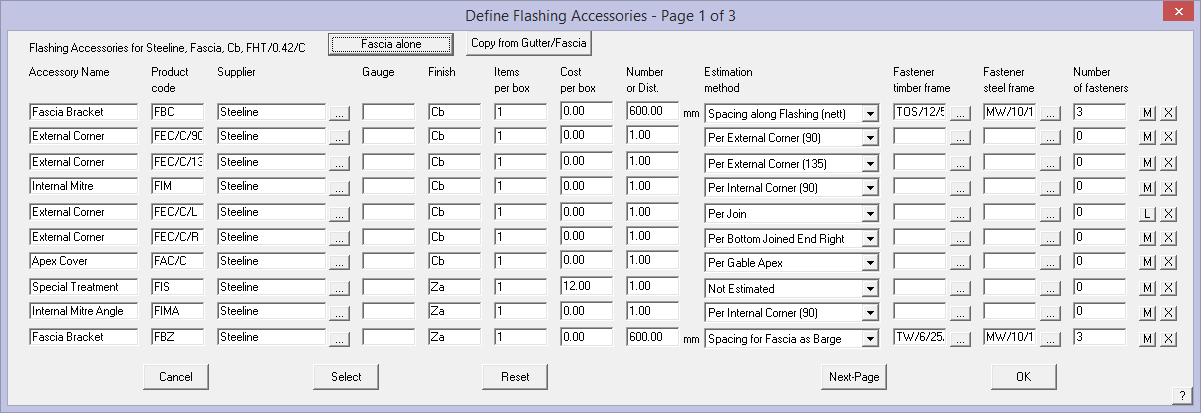

Special Pay Rates

Add-User Allows you to add any sort of labour charge that applies to your flashing and trim. Each new item is given a unique index number. The example below shows a new rate for ‘Tear-off and clean up’.

You might also set up a special rate for any flashing item that has extra processes that changes the cost compared with regular trim, say scribing hip caps or caulking ridge ‘Z’ bars. This new labour option will be available when you define the flashing item and select the Pay Rate Schedule. The alternate pay rate will be available to use. First select the variable pay rate with the special rate in it, then select the special rate.

Note: If no special labour options are required, then you do not need to set these up as it adds a further level of complexity when setting up your flashings.

Delete User Allows you to delete a user defined charge. You will be prompted for the index number of the item to delete.

The example below shows a new rate for ‘Special Gutters’.

Del-User deletes the new rate.

Next/Previous Page These buttons allow you to toggle between the two available pages.

[Cancel] Closes the dialog box without saving the changes you have made.

Intervals Lets you define the pitch intervals you want to use – see below, Interval Labels.

[OK] Closes and saves the changes you have made.

User defined pay rate for Special Gutters

Interval Labels

Customers utilising the GRIM output feature of AppliCad to link the estimation process to downstream systems have often had to create duplicate mappings of labour rates due to the output of variable labour rates in the Roof Wizard software. Outputs such as Ridge (1, 22.5) where the 1 specifies the storey and 22.5 specifies the pitch have had to create multiple mappings for each pitch gradient in 0.1 degree increments. In 8.2, we have provided the ability for each pitch interval to be given as a label (e.g. A, B, C as can be seen in the attached image) with the output therefore being Ridge (1,A), or Ridge (1,B) etc. This greatly reduced the number of mappings required, thus reducing the workload for our users and speeding up the interface between systems.

When you click [OK], the rates you defined are saved for future use. You may set up as many different files as you have different pricing for different profiles or wall systems.

Curved-Metal-Pay Rates

(Pulldown Menu)

This command displays the Installer Pay Rates for curved metal roofing box allowing you to set or change various labour rates associated with the installation of curved metal roofing. You select a pay-schedule for a job on the Cover > Select-metal dialog box.

Name This is the name of this pay schedule.

Storey This is the storey to which the following rates apply. A schedule can have up to 10 storeys

Pitch Intervals These are the pitch intervals you want to set for the job. You set them by clicking the Intervals button at the bottom of the dialog. To edit a column of values, you need to click on the interval value.

Line items For each line item you need to enter the rate per unit area or length for that line item. For roof removal and gutter removal, only the first rate is actually read when the Reporting is performed.

Select This button lists the existing schedules. You then select the one you want for editing. After selecting a schedule, the Update button appears letting you update the schedule.

Delete This button lets you delete the currently selected schedule.

Add This button lets you add the current schedule (schedules must have unique names).

[Cancel] Closes the dialog box without saving the changes you have made

Intervals Lets you define the pitch intervals you want to use

[OK] Closes and saves the changes you have made.

Nett-Rates

(Pulldown Menu)

This command displays the Roofing Reporting rates for nett-only roofing dialog which allows you to set the rates for the Reporting > Nett-Only command.

The values you set here are used by the Nett-Only Reporting method, to provide you with a quick and easy way to develop a quote using a pricing approach (rather than a cost up process).

Load Loads a predefined set of Net-Only rates for specific roof systems.

Save-As Saves a Nett-Only pay schedule for specific roof systems.

Here we present you with the option to supply material and labour rates for different parts of the job, which are multiplied by the nett quantities for the job (the nett quantities relate to the quantities displayed by the Tools > Tally-Quantities command). You can choose to set a rate to something meaningful or leave it at zero, and therefore has no impact on the quote.

So, if you have a rate per unit area you use to quote a job with, then this is the quickest and easiest method.

When you click [OK], the rates you defined are saved for use by the Reporting > Nett-Only command.

Wall Cladding Pay Rates

Wall Cladding Pay Rates

This function sets the installation pay rates for all components of walls and wall trim. They are all based on a cost per metre or cost per foot (depending on your units of measurement.

Name This is the name by which you select this pay rate in future.

Storey This is the storey to which these values relate. You can have up to 10 storeys for the one pay rate.

Select This allows you to select an existing pay rate schedule.

Delete This allows you to delete an existing pay rate schedule.

Add This allows you to add a new pay rate schedule.

Update This allows you to update and save changes to an existing pay rate schedule.

Auto-Fill Interval Automatically fills the table with the loading for each pitch interval.

Auto-Fill Storey Automatically fills the table with the loading for each storey.

Add-User Allows you to add any sort of labour charge that applies to walls. Each new item is given a unique index number.

Delete User Allows you to delete a user defined charge. You will be prompted for the index number of the item to delete.

Once the pricing table has the appropriate rates for each job function completely filled in, and don’t forget to do each storey, the file is saved away in the system using the “Add” button. if it is a new file; select Update if you’re changing details in an existing file.

Standard pricing files are stored within the software structure however user-defined pricing files are stored in a file called – SidingLabour5.csv.

When you click [OK], the rates you defined are saved for future use. You may set up as many different files as you have different pricing for different profiles or wall systems.

Quote-Groups

(Pulldown Menu)

The Quote-Groups option is a very powerful tool for controlling how much detail you supply the prospective client in your quotation or proposal. A quote group is a list of roofing items you want to group together on a quotation under a single price effectively ‘hiding’ individual line item prices.

The option is selected under Set-Up > Set up Pay Rates > Quote Groups.

For example, perhaps you want to provide a price for the roofing components (roof, ridges, hips and gables) and another price for the fascia and gutter (which may include valley and downpipes too).

- Create a quote group for each group of roof material categories;

- Review the price for that quote group (from the Reporting > Supply+Install > Quote Groups on-screen report).

- Print the report (you need to ensure that the key text string for each quote group is on the report template). For more details about editing Templates, refer to this section.

The list of line items that will appear in the list is stored in a pre-defined list as this was how the software was initially setup to work. Over time it became apparent that users wanted their own list, or have the items in a different order and the method of setting this up is described later – Customising Quote Groups.

CREATING A QUOTE GROUP

Step one in creating a quote group, you need to:

Enter a group name Enter a key text string (this is automatically generated for you as ###QGROUP1-n where the number refers to the group number).

NOTE: You can have a maximum of 20 Quote Group definitions, with a maximum of 50 items per quote group.

The Quote Group with “Remainder” in it must be the last quote group, otherwise the remainder gets swallowed up in the calculation and nothing flows through to the next group for Labour.

You must decide if you want the group name reported as well as the price, whether you want the tax amount to be displayed, will the final price include or exclude tax, whether it will include the mark-up percentage and if you want labour included.

Select the roofing material categories you want to be part of this group by clicking the button to the right of the category name. This button will then toggle to [Yes] and an asterix (*) or star symbol will appear alongside the category name. Enter a description for this category as you wish it to appear on the quotation report. If you don’t enter a description, the price of that category will be added to the total for the group but will not be reported as a separate item on the report.

Once the list is complete, you then select [Add], and that Group is added to the system database and effective for all subsequent jobs.

From the dialog you can easily select, update and delete an existing quote group. From the Reporting > Supply+Install dialog, you can see the results of the quote group by clicking the [Quote-Groups] button. The report for quote group 5 will be displayed and appear similar to the dialog box below:

This shows the line items which will be displayed, the calculated total, the material total and the labour total. You can also edit the bottom line price to a new value if you wish. The button to the right of the price field lets you set whether this price includes or excludes tax.

When you print the report, this group will be swapped for the key text string “###QGROUP5”.

Key Text strings are also created under the Key-Text String category of Quote Groups relating to the name of the quote.

These Key-Text Strings allow you to separate out the Material and Labour components of the quote group as well as the total price without the breakdown associated with the ###QGROUP Key-Text Strings.

| Key text string | Description |

| ###QG”QGName”-MatSubTotal | Sub-total of Materials for specified Quote Group name |

| ###QG”QGName”-LabSubTotal | Sub-total of Labour for specified Quote Group name |

| ###QG”QGName”-Total | Total of Materials and Labour for specified Quote Group name |

For example the above Quote group (Roofing) you will have the following Key Text Strings created, ready for you to insert into your report template:

###QGRoofing-MatSubTotal Gives you the Material Subtotal for that Quote Group

###QGRoofing-LabSubTotal Gives you the Labour Subtotal for that Quote Group

###QGRoofing-Total Gives you the Total price for the Quote Group

Preformatted tables are also available as Key Text Strings:

Key text string Description

| ###CostingDetailsTableQG | The costing details table is drawn with its top left corner at the origin of this text. Note that the width of the table is a fixed size. Items are grouped according to Quote Group definitions. |

| ###CostingDetailsTable1QG | This is the same as the costing details table above, but only reports the category, description and quantity and omits the costing fields. Items are grouped according to Quote Group definitions. |

| ###CostingDetailsTable2QG | The costing details table full format with tax is drawn with its top left corner at the origin of this text. Note that the width of the table is a fixed size. (Cost Price) Items are grouped according to Quote Group definitions. |

![]()

Note: All the Key-Text Strings are described here.

Customising Quote Groups

Quote Group Items List

The standard list before any alternative list is created has the items shown below:

If you wish to set up a different list or change the order of the list, you can do so by defining a new list and saving it as a file called QuoteGroups.DAT – a text file created in a text editor such as Notepad. The items in the list will come from the original list or from Alternate Categories list, and if you don’t want to itemise everything, list the key items and then use ‘Remainder’ as a list item and everything else will be included in this item in the group.

New item names can be created and this is described using AltCategories described below:

A good starting point for a QuoteGroup setup might be a Fascia and Gutter group and a Roof group and that QuoteGroup file would look like this:

QuoteGroups (if you wish you could copy this file and save it to your ..\User folder.)

and the custom list for this quote group would require the QuoteGroup.dat file set up as described above.

Remember, as stated above, the Quote Group with “Remainder” in it must be the last quote group in your list of groups, otherwise the remainder gets swallowed up in the calculation and nothing flows through to the next group for Labour rates.

Editing the Quote Groups

The Quote Groups dialog is comprehensive and in some situations, may be simply too much information being reported on individually. The Quote Groups are stored in the text file created by the software called QuoteGroups.csv (a CSV file is a Comma Separated Values format that may be read in Excel) where the groups can be defined.

The setup of the Quote Groups may be substantially simplified by editing the file in a text editor such as Wordpad or Notepad which are Windows utility programs. However, for most users MS Excel will be the preferred editor, and when opened will look like this:

The structure is obvious and allows you to be very creative in how you build your client quotations or export job data to other systems, within limits. The Index number is extracted from the QuoteGroups.DAT file, the list of Quote Group category items. The category names are used in the picking up of items, as this is more useful to specify items exactly. Unless you specify a category name in the DAT file and select it to be included for a specific group, it doesn’t include it. Add any new categories you need to the end of the list instead of trying to make everything alphabetical or grouped or the index number doesn’t line up with the category.

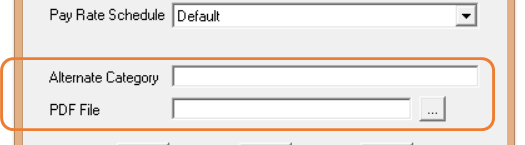

Export Pricing Data by Category

Roof Wizard is moving towards an improved pricing and job management solution, with linkages to external accounting systems, a requirement to allow splitting up of an estimate into various groupings became apparent. The best way to do this is with Quote Groups, and so the ability to modify the default “category” for each material item in the software has been provided for on each data entry dialog box.

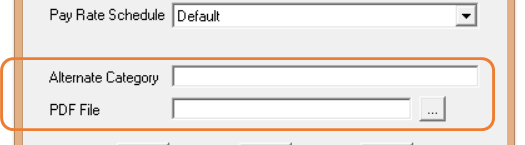

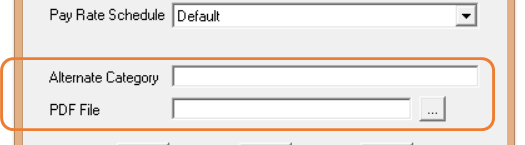

To further fine tune your reporting of material and labour items, you can define an Alternate Category. This allows you to define a different category so that the tile (in this example) may be listed under a different group in the [Supply Only] or [Supply and Install] summary list.

For example, here we need a snow retention bar included in the Fascia and Gutter Quote Group. So we change the definition of the part to show as an Alternate Category – Snow.

When we go to Reporting > Supply Only/Supply and Install, we can see that the Snow Strapsare in our material list, but also have an Alternate Category “Snow”.

So now we can add “Snow” items to our Quote Group.

Once included, this item and the cost for this item will be included in the Fascia and Gutter Quote Group as a single aggregated sub-total cost.

There are limits – you can have a maximum of 20 Quote Group definitions, with a maximum of 50 items per quote group.

Note: All items that are not specifically listed in a Quote Group will automatically be added to a Quote-Group called Remainder.

Preference Settings

System Preferences

This command sets various operator preference settings such as the units, slope input and terminology of your installation. You should only have to set these options once. There are a lot of options here and setting them incorrectly may change the way the software works for you, so be sure you understand what you’re changing, and why, before you change it.

When you select System Preferences, the Preferences dialog box is displayed:

- Left column of System Preferences Table

Input pitch as This is either Degrees (°) or Slope (in 12) or percentage (in100)

Units This is either Metric or Imperial

Terminology This is either English or American

The differences in terminology are

[Aust-English / American]

Sarking/Underlay

Battens/Purlins

Verandah/Porch

Cartage/Delivery

Downpipe/Downspout

Shell end/Hip starter

Apron/Skirt

Barge Rake/Verge, Rake

Colour/Color

Labour/Labor

Step/Roof-to-wall

It is fair to say that the terminology differences are notional only as regional differences also exist that make such a process flawed from the start.

Currency Symbol You can set this to any character or group of characters you want.

Currency Field Width This is the number of digits you want to be able to see in currency fields on the Reporting dialog boxes. If dealing in US or Australian dollars, the default is adequate. For Italian lire and Filipino peso, you may want to make it larger.

Number of Outlines to Save The number of job perimeter outlines saved to the file in date and time order, for later recovery under Const-Roof > Recover. Default is 20 but may be set to any number, say 100 or 150 for example.

Tiles Database to Use This is either Tiles or Tiles+. This selects the particular tile data file structure you wish to use for the Cover > Select-Tile command. They are not inter-changeable so be sure to read the respective descriptions in this manual to understand which one you should use.

Costing – Merge Same Product Code Items Y/N – sets whether you want items with the same product codes to be merged into one line item in the material list under Reporting > Supply Only or Supply and Install. This function searches the job Reporting data for products that may be used for different applications (such as screws) but are actually the same product and product code, and adds them all together as one line item on the quotation.

Import GRIM File on Start-Up Y/N – Allows you to turn on or off the Import GRIM file process when you open the software.

Allow Editing of Pricing Files Y/N – Allows the administrator to set a password on editing material or labour pricing files to make them tamper tolerant. A blank file called sysprefspwd.dat is shipped with the software. This does not make the files tamper-proof, but it will certainly slow down unskilled or unauthorized users.

By default, the setting is Yes allowing anyone to edit any pricing file. If the option is set to No pricing options in all materials and/or labour under Set-Up are not accessible to the operator – they appear ‘greyed out’ on the dialog.

Allow Multi-Language Y/N – This option allows the software to operated in any language. All functions and dialogs now refer to an external file for the appropriate prompt to be displayed. By translating the files, there are 90+ files, to the required language the prompts will be displayed in this language. At time of printing German and Spanish are available and French is in the pipeline. The files must be saved in the folder ….\AppliCad\<program>\Language.

Number of Segments to Break Arcs into The software will only generate roofing and cladding to lines, but if an arc is found, that arc may be divided into line segments so that the geometry for the roof or wall will still be constructed correctly. Effectively the number of segments sets the resolution of the arc.

Hide On-Screen Command Hints Y/N – Allow the display or hiding of on-screen tooltip hints (on by default).

Show Word/Excel Processing Shows each stage of the output being processed as the report is generated. Only applies when the report is being generated from a Word Template or Excel spreadsheet.

Excel – Columns to Process Limits to range of cells in Excel to process. Useful if the total matrix of cells is large.

Excel – Rows to Process Limits to range of cells in Excel to process. Useful if the total matrix of cells is large.

Leave Word/Excel Documents Open This leaves Word or Excel open with the generated report displayed. This is useful to make further edits or check the result before printing.

Show Zero Qty Line Items in Costing As it suggests, enables the option to display the zero quantity items in the costing report screen (Reporting > Supply Only or Reporting > Supply and Install). You would leave on so that you can modify the quantity to add an item. This may be used as a prompt for occasional use items such as fuel surcharges etc. Create a bunch of Extra Items with zero quantities and they become your check list.

Automatically Print Word/Excel Reports/Drawings Y/N – When set to Yes, the report is printed to the default Windows printer, as soon as Word or Excel completes creating the report from your template.

Use Commercial Mode Y/N This option enables the use of Substrates, Systems and Assembly Groups for specific large scale operators interfacing with very large material databases and assemblies. Not for general use. Leave set to No unless specifically requested by the AppliCad Support department to change. It requires all trim, accessory items and assembly groups to be defined BEFORE use. This includes telling each metal panel which assembly applies when Commercial Mode is enabled. You cannot do ‘half this’ and ‘half something else’.

Add Product Codes to Metal Panel Labour in GRIM Oot Y/N – allow the labour product codes to be output to the GRIM output file. We’ve provided this switch so as not to change the GRIM file format for those who have written programs to read in the file format (post V8.2).

Show Newer Job Info Dialog Y/N – allows the Job Info dialog to switch between the version with ‘WindZones’ and that with ‘Notes’ (see description of JobInfo) below.

Use Block-Cutting Dimension Dependencies Y/N

This adds the button [Block Cutting Dimension Dependencies] to the functionality of Panel Labelling, by providing a dimension insertion option within Block-Cutting, as well as adding the block reference into the dimension. Note – the [Dimension Reference] function must be enabled in System Preferences for it to appear in the dialog and to use. Read about it in System Preferences so that you understand the purpose, before you turn it on.

This adds the button [Block Cutting Dimension Dependencies] to the functionality of Panel Labelling, by providing a dimension insertion option within Block-Cutting, as well as adding the block reference into the dimension. Note – the [Dimension Reference] function must be enabled in System Preferences for it to appear in the dialog and to use. Read about it in System Preferences so that you understand the purpose, before you turn it on.

Use Flashing Identifiers Y/N – The same applies to Flashing annotation, with the additional functionality that flashing labels can be grouped by just their length, or additionally by a line also. If set to this latter option individual lines, despite having the same flashing type and length, will still have a separate identifier so that they are more easily identified on the drawing, and where the material is to be installed on the roof, thus greatly assisting the installers position materials around the job.

See example below for a Soaker Flashing along a Step line.

Reverse Name/Desc for Insulation Y/N – The ability to swap the use of the Name and Description fields for Insulation/Underlay selection ensures the product “Description” aligns with the “Finish” of the estimated product when listed in the Supply & Install dialog.

File Directories These are the directory(s) or folders where the system will look for your data files. These are the data files containing material definitions, report templates and labour rate details (.csv, .dat and .bin and some .dab files). It may include the CAD (.dab) files you create for your jobs. If there is no directory path, then the system first looks in your ../User directory. If the file is not found there, it looks in the ../Programs directory.

You select a new folder or directory by clicking the ‘…’ button. Clicking the ‘x’ button will reset the folder or directory to nothing. If you wish to use a folder or directory on a file server so data files are accessible over a network, you will first need to map the network drive using Windows Explorer.

The option exists to define separate folder for the output of the GRIM file, thus eliminating the need to copy the file on completion of the report.

Setting User and Corporate data Folders

The directory/folder structure has been implemented to provide for more comprehensive data and job file management, especially at larger sites with many operators. If you are a single operator, keep it simple. The default settings for folder locations are as displayed – local drive, C:/AppliCad/Roof Wizard/User or D:/AppliCad/Roof Wizard/User. If you need to access any file such as an image file of a roof, a PDF or even a backup of a .dab (job) file, copy it to the ../User folder before you open the software.

It is expected that multiple users on a company network will save all their work and access data files from a common shared drive. This ensures that all users are accessing the same pricing data, jobs are available to everyone for checking or reporting and the system admin is backing up everyone’s work at once.

Corporate Folder – The software can be set to search the “Corporate Folder” prior to the “User Folder” when looking for databases, models, CSV files etc. This function will allow the user to copy a number of “Corporate Default Settings” to the Corporate folder and by setting this switch to [Yes], will ensure these options are found by the software before being located in the User folder. Thus, Corporate Standards for the software appearance, units, setup files etc will be able to be maintained more easily while still allowing specific job settings to be set by the user. To enable this, it is appropriate to set the option Reverse User/Corporate Folder Search [Y/N] in the Preferences as well. This provides considerable flexibility in how job files are saved for access by all networked users while allowing individual user settings to be maintained.

GRIM Folder – This is the path you set for exporting the GRIM text file to. This is set so that any other programs that you might interface the results of our software with, can find the GRIM data and picked up automatically.

Report Folder – You may also set the folder where you want your Excel or Word reports to be saved by default. This is so that you can keep those people checking reports (cutting lists, quotations etc.) away from the working folders (typically ..\User) and reduce the potential for unauthorised modifcations to the pricing and product specification settings. Note that the standard CAD reports will not be saved to this folder as they are typically sent directly to a PDF and saved as a part of the job model file as a model with the prefix REP- for a report or DWG- for a drawing.

Temporary Folder – This folder is typically a sub folder below the ..\User folder. It is where temporary files that are generated as part of the process of creating cutting lists and pricing are saved. These files are re-rcreatd each time a job is processed and are not required after the report is generated. It is good housekeeping to go into this folder on occasion and delete the entire contents of the ..\User\Temp folder so they do not ‘clog up’ the disk storage.

For a summary of file types and where they must be located for correct operation of the software refer to the File Types and descriptions at the end of this document. Set the path to folders according to your system set-up. If you are unsure, please refer to your System Administrator or IT expert, or call the AppliCad Support Team. If these are not set correctly all sorts of weird things can happen.

Note that when setting file paths and ‘start-in’ folders, this is not only setting to check. There are other settings to be checked as the software starts starts up and subsequently finds the initial program setup information such as version details, units etc. and this is described below.

Setting the Network File Sharing Location

The software is a single user license product – one license, one user. However, the software is network aware and allows you to save work on a shared network server drive so that printers, material definitions, settings and job files may be shared with other users. If you are not sure about this, engage your IT guy to help.

If you need to check and/or set the paths for the software to look in the correct location for its data – there are four locations where you need to check/set the file path. Setting up connections to a shared drive, such as Z:/AppliCadUser is described here.

Note: If you are not sharing files on a network, then the default location is C:/AppliCad/Roof Wizard/User. You can also use the steps described here to check that the software is pointing to this location instead of the example used. If you have navigated away from the ../User folder and opened a file, then the software remembers the new path and then will not be able to find all your system settings and pricing files etc. As explained above, if you need to access any file such as an image file of a roof, a PDF or even a backup of a .dab (job) file, copy it to the ../User folder before you open the software.

- Right column of System Preferences table…

Currency Precision (Reports Only) This allows you to set the number of decimal places you want your currency to appear on your reports only.

Tax Name This is the name of the taxation system in use in your country. (eg: GST, VAT, Sales tax). You will see this value displayed on the various Reporting dialogs and the reports where tax is required.

Tax Percentage This is the tax percentage you want to set.

Payment Terms for Job Details This is the payment term you want to appear on your reports.

Use File Locking (Networking) In larger firms where the estimating office has multiple operators doing estimates, file locking restricts the operator from opening a job already being worked on by one of their colleagues. This prevents inadvertently over-writing some else’s data-files. If the software has been closed in error and lock files have not been properly cleaned up, it may be necessary to delete them. This may be done with the button – Delete to delete existing lock Files – these are files in the …\User folder with a *.LOC extension.

To prevent other operators opening the same model database (a *.DAB file), you must also enable the CAD file locking. To do this go to CAD > DEFAULTS > System Settings > Setup from the pulldown menu and enable File Locking. Make sure that the lock file directory is also setup to point to a folder in the shared network, …\User folder.

In this example, Y:\Share where Y: is the shared network drive and the Share folder is the folder where the CAD lock files are created.

The CAD lock files have the database file name with a *.LCK extension.

Default Tiling Estimation Method (Area/Coursing) Presets the estimating method quantifying tiles, shingles, shakes and slate – the options are by Area or by Course. Area calculates quantity based on pieces or bundles per square and Coursing actually lays the pieces course by course on the roof model and then counts the pieces. (Waste, if defined, is applied later, during the cost reporting operation of Supply Only or Supply and Install).

Allow Plotting to PDF files Y/N – Allows the operator to print directly to PDF files. Requires a third party PDF generator such as Adobe Acrobat™ or PDF995™ to be installed (not supplied by AppliCad Software).

Job Wizard on Start-Up Y/N – If set to Yes, the Job Wizard guides the operator through the steps of creating and estimating a job. This is especially helpful to new operators and is usually turned off once the process is learned and understood.

Use Stage Manager Y/N – Turns on the stage manager function if you require the ability to break a quotation down into Stages – refer to Stage Manager elsewhere in this manual for more details of Stage Manager.

Copy Database Locally before Open Y/N – Added option to “Copy DABS Locally” which will result in database files being copied to the local machine before being read by the software. This switch can improve database read and write speeds across slow WAN and LAN networks.

Use Interval Labels for Labour Y/N – allows the output of labels set up under Set-Up > Metal/Tile Pay Rates Variable > Intervals to be displayed in the Labour dialog of the Costing > Supply&Install dialog and also to be output in the GRIM file exported – (Set-Up > Pay Rates > Metal/Tile Labour > Intervals)

Use Costing Plus Y/N – this function allows the software to use the Tiles+ tile structure and the Costing+ pricing structure to make comparisons with cost and sell price to determine profit margin.

Excel – Columns to Process Limits to range of cells in Excel to process. Useful if the total matrix of cells is large.

Excel – Rows to Process Limits to range of cells in Excel to process. Useful if the total matrix of cells is large.

Output of Material Cutting List Y/N – This allows you to change the output of your material cutting list, from Feet & Inches to Inches only.

Note that this is only applicable for those working in Imperial measurements. It is not displayed when in Metric units.

![]()

When set to [Inches Only], this changes the cutting list tables for Section Reports and the output to the various rollforming machine cutting list formats [Export to Rollformer] to inches.

Use Roof Area if no Panels Applied Y/N – If no panels have been appied to the roof model, the roof area will be used as the roof area quantity for material cost purposes (based on the cost per square (foot or metre) of the selected material item.

Show Print Dialog when Printing Y/N – If you have a single printer then typically you would set this to No and it will go directly to that printer. If you have a range of printing options as you might have on a network, then set to Yes and select the required printer to send the print job to.

Reverse User/Corporate Folder Search Y/N – Allow the software to search the “Corporate Folder” prior to the “User Folder” when looking for databases, models, CSV files etc. This function will allow the user to copy a number of “Corporate Default Settings” to the Corporate folder and by setting this switch to Yes, will ensure these options are found by the software before being located in the User folder. Thus, Corporate Standards will be able to be maintained more easily while still allowing other settings to be set by the user.

Treat Gutter/Valley Intersection as a Stop End Y/N – Allows you to modify the way in which “Stop End” accessories are calculated where an Eave, a Valley and a Raking Line come together. It effects the way accessories are calculated.

![]()

Update Panel/Tile Definitions during Costing Changes made to an estimate do not always flow through to the Supply & Install dialog, as we often found with metal panel changes and tile, shingle and shake selections. Sometimes this is deliberate (estimators comparing relative pricing for materials) but often it is unintentional and leaves the chance open for the incorrect product to be specified from what the estimator was intending. As such, this switch can be set to check these major component items such as metal panels and tile/shingle/shake systems that indicated by the prompt – [Panel/Tile Definitions have changed, do you want to Update dialog to software?]

GRIM Out Unique Fabrication Codes in Pricing Y/N – , the ability to output Custom Flashing product codes, as specified in the Multi-GRIM Quotation Output dialog, can now be enabled through the Supply & Install dialog also, allowing these product codes to flow through to the reporting. Specification of the file containing the Custom Product Codes then needs to be specified in the Quoting > Multi-GRIM Out > Multi-GRIM for Quotes dialog, with the file containing relevant Product Code structures for each manufacturer.

The ###GIRTH, ###BENDS and ###CODE sub-strings can be used to automate the creation of the new product code – as described in MultiGrim setup.

The resultant product code will then be constructed for each Custom Flashing and will appear in the Supply & Install dialog and flow through to the reporting, thus ensuring reporting and GRIM output results match.

Plane, Roof and Wall Line Options

Displays a dialog box to select what plane or line options you wish to set up.

Roof/Wall Plane Options

Selecting Plane Options brings up the following dialog box where the operator an set whether roof and wall planes are displayed as a filled area or as cross-hatched lines.

If Filled Planes is selected, the Filled Plane Intensity needs to be set, making the filled planes lighter or darker. We have found that a plane intensity of about 0.35 or 0.4 works well.

Any category of material can be set to any colour number. Any colour number can be any colour, set using the function CAD > Defaults > Colour Table (more information below). Remember that these colour numbers may be used for many entity types, so if you change colour 10 for this purpose, it might not be what you need where colour 10 is used elsewhere, for a line type for example.

Once set, select [Apply] and the new settings are applied to your job. These settings are saved with the job when you select [File > Save].

If Roof/Wall Plane Style is set to [Hatched], then you get extra options to set for the line style used for the hatch pattern: Style – whether it is a dashed, dotted or solid line; and Weight – the ‘thickness of the line when displayed on screen and plotted on the report page.

Roof model with Filled Planes

Once set, select [Apply] and the new settings are applied to your job and are then used on all subsequent jobs.

These settings are saved when you select Apply, [OK] and then [OK] again in the Preference Settings dialog. They are also saved with the job when you select [File > Save].

Roof model with Hatched Planes

Roof/Wall Line Options

This command lets you set the colour, style and weight (line thickness) of the different line types in a roof and wall model.

When [Set Line Styles] is selected the roof line styles are displayed and may be changed to suit the personal preferences of the operator. The Line Function is the name Roof Wizard uses for a line, the Name is the term that the operator wants that line to be called. Once changed, that name is used throughout the program, where ever that Line Function is used. Obviously it is preferable that each line function has a unique name. Set line colours, styles a line weight to suit the needs of your office. If you have a dark background in the program’s workspace, then dark lines will be hard to see. Similarly, white lines are impossible to see on a white background. When selecting line colours, also consider the output reports. Most of us print onto white paper, so select line colours that will be legible when printed!

Extra User-Defined Line Styles The operator may define 4 additional line styles or categories for use on the roof model – USER1 to 4. Once the names are defined, they become visible throughout the Cover > Flashing type options and also for Tools > Change Line Type options.

When you select [Apply], the changes are made to the lines in the current model and the dialog box remains displayed. When you click [OK], the settings are saved and are used for lines inserted from that time on.

Regardless of what name is used, the line style function is as described in the second column. This is important to keep in mind when setting up flashing and trim options under the Set-Up > Flashing command.

When you click the colour setting button, the Defaults Colour dialog box is displayed.

Here you click the colour number you want, and then click [OK]. You will then see the colour index transferred to the Set-Line-Styles dialog. This changes the colour number. A colour number may be any colour. The colour map for each colour number is defined using the Defaults Colour Table accessed by selecting the [Define] button.

Select from the basic colours, or define a custom colour by using the Hue, Saturation, Luminosity scales or the Red, Green, Blue scales. Once selected, select [OK] and that will be the line colour used. Make allowance for the screen workspace background colour settings you use as well as how the selected colour will appear on a printed report and indeed, whether you are printing in colour or monochrome.

Line Style and Line Weight

Selecting the line style and line weight is similar in operation.

Below is the Defaults Style dialog box. Selecting a style number changes the line style for that line category. For example, valley lines are often selected to be a dashed line to highlight them against hip lines.

Below is the Defaults Weight dialog box.

The [Show Angle] option displays the angle of bend for the trim, which is the angle between adjacent roof planes. It becomes part of the information that describes the flashing/trim profile in the flashing cutting list, thus assisting the correct pfabrication of the part. When selected, the X appears in the cell.

To set, simply double click the cell on the dialog and then the fabrication angle of bend will be displayed as part of the flashing report as shown below in the cutting list summary – similar to the list below.

When checked, the software will add the angle of bend to the annotation of the roof plan as well, thus allowing installers to install the correct trim to the correct edge. This is particularly useful on complex roof shapes with multiple roof pitches.

Note: The line annotation is only applied to the drawing when the trim is manufactured ‘cut to length’. If your trim is manufactured as stock length ‘sticks’ of say 10’3″ or similar, then the lines are not annotated as all the lengths are the same. If you have a range of bend angles, (caused by multiple roof pitches) then the lines will be annotated with the bend angle only.

Also note that you must set the estimation method to calculate each run separately – NOT total run. Refer description of setup for estimation methods below.

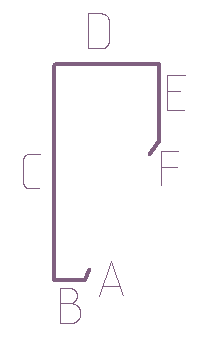

Notes regarding Single-Slope trim at the top edge.

In parts of Australia, they call the top edge of a single slope flat roof a ‘monoridge’. As you know we have a line type called Monoridge but be aware that this was something we developed 30 years ago specifically for Tile roofs. Flashing is not applied to this line type unless you create a User line called MonoRidge in the preferences. However, this is not the best option.

When set, it doesn’t do anything when applied to a metal roof. It is very specific to tiles in the current setup.

So, when you try to generate a flashing cutting list, nothing is identified for the Monoridge line types.

Turn on the [Show Angle] function for Gable line types; set the ‘monoridge’ line to ‘Gable’ on the model and the software takes care of business for you, generating the correct cutting list for each part of the roof including all components for the roof.

Remember, by default, the software creates an Apron line type at the top edge, assuming that the single slope roof is going to butt up to a wall.

Where it is free standing single slope roof, not joining anything, the ‘Gable’ linetype is the best option, definitely NOT Monoridge, unless it is a tile roof.

With this set, you get the following result, which is 100% satisfactory for our friends in Queensland (Australia) and other places where this is critical for the correct material to be fabricated and shipped to site. Both Barge cap, bent to the correct angle for each situation on this roof, and Fascia-as-Barge are calculated and listed separately in the cutting list.

When accessories are defined the correct accessories are also calculated.

Nice and tidy!

Dimension Default Settings

(Pulldown Menu Only)

After selecting Defaults, the Dimension defaults dialog is displayed.

Dimensions Defaults

![]()

Note: Typically, the font used to annotate roof planes and drawings is the font defined under CAD > Defaults > Text Defaults. As these may change from user to user, it is suggested that a text file called Fontfile.dat be created and saved in the User folder, thus ‘locking-in’ the required font style for each user. The font used on the roof plan for annotation such as area, azimuth etc will then be determined by the font defined in the Fontfile.dat. True type fonts will be listed by their name only (such Arial or Calibri) and the CAD fonts by the name and the extension (such as HELV.FON for Helvetica font or ISO.FON for CAD ISO font). If no font file exists (it must be created by the user) then the CAD text default settings will be used.

Dimension Sizing Options

These options allow you to alter the size of dimensions for the four different methods. You will see the effect on screen and on the printed drawings.

Coursing Dimension Specific Options

Set the height of the course dimension text and also the information to be displayed on the roof plan. For example – Coursing (Eave ###E mm / Int ###I mm) would insert Coursing (Eave 350mm / Int 310mm) on the drawing as shown below.

Ln-Ln Dimension Specific Options

Round Length Dimensions to .. sets the rounding up of the dimension number drawn on the roof drawing – in the example ±10mm.

Match Line Dimension Colour changes the dimension colour to be the same as that set for the line making it easier to associate a dimension with the matching line. If set to no, the default settings for dimension are used.

Dimension line Lengths Greater Than allows the operator to set how short the shortest lines to be dimensioned will be. Anything shorter than the specified length will not be dimensioned. This takes the clutter out of the drawing by not dimensioning lines that may not be important.

Dimension Distance Off Line sets the distance the dimension is to offset from the associated line – roof plan on the left is set to 0; roof plan on the right is set to 100mm.

![]()

Note: Be careful switching between metric and imperial units as this can have a detrimental effect on settings such as arrow size – 100mm in metric becomes a 100” in imperial.

Without offest from the referenced line.

With offset from line set to required distance.

Azimuth/Area Dimension Specific Options

Round Area Dimensions to sets the rounding up of the area dimension number drawn on the roof drawing – in the example ±1sqm.

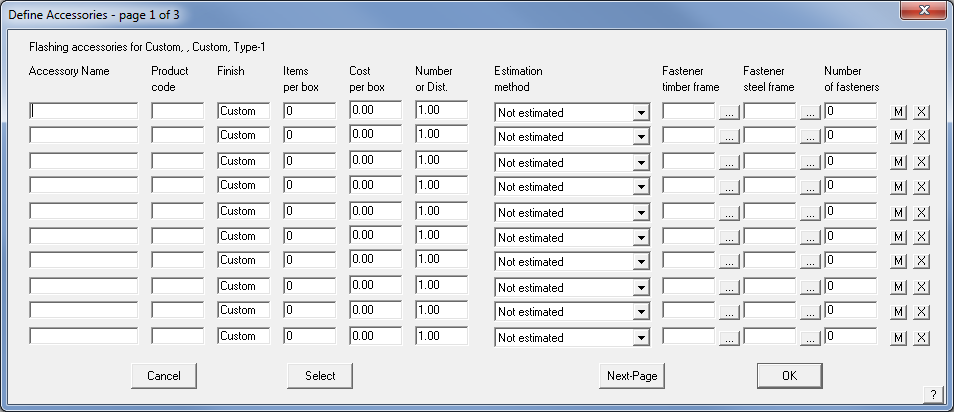

Azimuth Dimension Precision sets how many places after the decimal point.