Contents

- 1 Reporting

- 2 Reporting > Supply-Only

- 3 Reporting > Supply+Install

- 4 Fascia-Gutter

- 5 Nett-Only

- 6 Drawings

- 7 Pay Rates

- 8 GRIM File Format

- 9 Report Templates – Microsoft Word/Excel

- 10 Report Templates – CAD

- 11 Reporting Key Text Strings

- 12 Data File Formats and Data Structures

Reporting

The reporting stage is where you generate the material and labour (if required) summaries. Once the pricing details have been checked, it is here that you select the reports that you need to generate and print from the huge amount of detail automatically created by the Roof Wizard estimating process.

The reporting stage is where you generate the material and labour (if required) summaries. Once the pricing details have been checked, it is here that you select the reports that you need to generate and print from the huge amount of detail automatically created by the Roof Wizard estimating process.

Extracting the vast amount of information that Roof Wizard generates requires you to have the report templates defined to display this information. Initially, this may be seen as a complex process, but once mastered, it is awesomely powerful in extracting and providing information to all parties – from suppliers to installers and everyone on between.

Note – The primary difference between Supply Only and Supply and Install is that Supply and Install includes installation labour costs. The description of both sections below should be read and understood.

Reporting > Supply-Only

Reporting > Supply-Only

When you select Supply-Only, all the materials are tallied, sorted and displayed on the Supply-Only dialog box. The title on the dialog box describes the name of the current quote as well as what page is displayed.

In calculating the material and labour items required, the software pauses to check if any EXTRA items have been defined that are set with the [Prompted] option (refer to set of EXTRA items for details). If any are found, then the dialog box is displayed showing all items setup to be prompted for, prior to finalising the quotation. Select the required items for this job and click OK. If multiple items need to be selected, hold down the CTRL key and select all requried items in the list.

This process allows you to add items, labour or material, that may be required on a job, but not a function of the roof size or type. It can include all sorts of additional costs that must be included in the job quotation.

The Reporting for the job takes account of stages defined using Stage Manager such as first storey, second storey or roof material and trim. Please refer to the detailed description of Stage Manager to know how this is applied.

Along the top you can see columns called Category, Supplier, Description, Qty, Rate, Subtotal, Discount and Total. Each row represents a single material item ranging from the roof cover material to gutter brackets.

Supplier This is the name of the supplier of the item

Description This is the description which combines the description of the item and finish

Qty This is the quantity of each item derived from the estimate process. The unit for the quantity is described in the above table.

Rate This is the rate per item

Subtotal This is the sum of the quantity and rate

Discount This is the discount percentage you want to apply for that line item. The default value is the discount associated with the selected customer. If the value is set to a negative number, a mark-up is applied. The Discount may be pre-set for each customer – set this in the Job Info > Customer section – as shown here.

Total This is the total for this line item after applying the discount.

Below the Total column is the Job total field which is the total for the job, not just for the page you are looking at, if there are multiple pages.

The buttons at the foot of the page are:

Category – this value is simply a shorthand description of the type of item described in the following table.

| Category Name | Type of material | Unit |

| Straight | Straight metal roof material | M²/ft² |

| Curved | Curved metal roof material | M²/ft² |

| Ridge | A ridge flashing | M/ft |

| Valley | A valley flashing | M/ft |

| Fascia | A fascia flashing | M/ft |

| Gutter | A gutter | M/ft |

| Apron | An apron flashing | Mft |

| Barge | A barge (rake) flashing | M/ft |

| Step | A step flashing | M/ft |

| Batten | A batten material | M/ft |

| Flat Sheet | Flat sheet metal for custom flashings | Each |

| Fabrication | The total fabrication cost of the custom flashing | Each |

| Fasten | A fastener type | Boxes |

| Clip | A type of clip for standing seam panels | Boxes |

| Accessory | A flashing accessory item. | Each |

| Membrane | A membrane material | Roll |

| Roof tiles | Roof tiles | Each |

| Ridge tiles | Ridge tiles | Each |

| Hip starters | Hip starter piece | Each |

| Apex tiles | Apex piece | Each |

| Roof shingles | Roof shingles | Each |

| Ridge shingles | Ridge shingles | Each |

| Apex shingles | Apex shingles | Each |

| Roof shakes | Roof shakes | Each |

| Ridge shakes | Ridge shakes | Each |

| Apex shakes | Apex shakes | Each |

| Starter course | Starter course material for shingle and shake roofs | Each |

| D Pipe | A downpipe | Each |

| D Access | A downpipe accessory which could be a pop, offset, shoe or elbow. | Each |

| Extra | An extra item read in from extras.dat | Each |

| Insulation | An insulation material by the roll | Large or small |

| Ccharge | The curving charge | One off |

| Cflash | A curved flashing | Each |

| User Length | A user length value (eg vermin proofing, bird stop etc.) | M/ft |

| User | A user defined item | Each |

| Misc | A user defined item from Misc-Item | Each |

| Cartage | The number of items to deliver | Each |

![]() Note: There’s currently no way to order the items within each group (Roof/Wall Cover, Flashings/Fittings, Accessories, Fasteners) in the Supply list dialog. However, you can decide what appears in each category group, as well as the individual names of the groups. It requires you to define a category sort file.

Note: There’s currently no way to order the items within each group (Roof/Wall Cover, Flashings/Fittings, Accessories, Fasteners) in the Supply list dialog. However, you can decide what appears in each category group, as well as the individual names of the groups. It requires you to define a category sort file.

A file external to the software “Categories.CSV” saved in the \User folder, can be defined which allows for modification of these items. See the example here opened in MS Excel:

The first 4 lines define the names of the Category Groups in the Supply & Install dialog.

The remaining lines after these first 4 define category names and which category group they should be placed within. The software has default options built into it, but in the example here you can see that by placing anything with a Category name of “Spout” into Group 2 (Accessories), anything with a category name of “Extra” into Group 1 (Flashings/Fittings) and anything with a category name of “Wall Insulation” into Group 0 (Roof/Wall Cover).

Quote-Groups

This button takes you to the Quote Groups section showing you the prices for each quote group setup previously.

Each group contains the line items that will be ‘aggregated’ to create a single total cost for that group of items so that a sub-total cost for this group can be displayed on the quotation. Thus not displaying each line item cost in the quotation.

The example below has five Quote Groups – Fascia and Gutter group is displayed.

Once a Quote Group is defined, you can then create a report template that incorporates the Quote Group Details using key text strings for that group individually or as a table.

| Key text string | Description |

| ###QG”QGName”-MatSubTotal | Sub-total of Materials for specified Quote Group name |

| ###QG”QGName”-LabSubTotal | Sub-total of Labour for specified Quote Group name |

| ###QG”QGName”-Total | Total of Materials and Labour for specified Quote Group name |

For example for the FasciaGutter quote group described above you would use –

###QGFasciaGutter-MatSubTotal

###QGFasciaGutter-LabSubTotal

###QGFasciaGutter-Total

Refer to Key Text description for more details.

Changing Displayed Values

Double click the line item description allows you to change the item description for any of the items listed. The change you make is relevant to this quotation only and does not effect the definitions previously set under Materials. Change as required.

Any line item displayed in the Supply and Install list can be modified by double clicking the line item. The description can be changed and a calculation can be typed into the field.

Export Acct.

This button allows the details of the costing screen to be exported to a file that may be read into your accounting system. This presumes that your accounting program can read such files. The path for writing the file would be such that the accounting program picks it up and reads it automatically. The format is a simple comma separated values file (CSV) with each item listed as displayed in the costing dialog..

Similar to this:

Export GRIM

The Export GRIM button saves atext file in the format of AppliCad’s proprietary GRIM format. This provides a method of exporting every single bit of information anout the job from material and labour costing to panel and trim cutting lists. The GRIM file is described in detail here.

Delete Use this button to delete a previously saved quote.

Notes

When you click Notes, you next click the form report name you wish to attach a note to. For each of the standard CAD template forms, if it has a ###QQnote key-text-string, then the relevant note will appear on that CAD template form.

When the note is formatted on the report, line breaks you typed in are ignored since the notes will span the “text width” value of the ###QQnote text entity. If you want to force a line break, you must use the ^ (carot) character in the note text. The standard notes are usually defined under Tools > Define Notes. However, you can also add/edit your standard notes from the Notes function within the Supply Only or Supply and Install dialog box – the same steps apply.

Save

You can save this quote by clicking Save, then entering a name for this quote. Then you can redo another quote if you wish. The job details are saved in the Quotation Register and listed by date and time. Refer to Quotation Register explanation in the next section.

![]() Note: If you define a text file called QuotePresets.dat you can pre-set a series of pre-defined quote names to ensure that the standard quote name is used or simply to speed up the process. Once defined, the available names are displayed when you select Save from the Nett Only, Supply Only or Supply and Install dialog box.

Note: If you define a text file called QuotePresets.dat you can pre-set a series of pre-defined quote names to ensure that the standard quote name is used or simply to speed up the process. Once defined, the available names are displayed when you select Save from the Nett Only, Supply Only or Supply and Install dialog box.

Load You can load a quote you have previously saved for this job.

Print Here you can print to any predefined reports. You can select the reports you want to print on the select [Reports to Print] dialog box similar to that shown below. The reports listed may include any extra report templates that you may have created.

Refer to the section later in this manual for how we create report templates and add them to this list.

After you click [OK], each report is prepared and then sent to your printer. Like the other reports, the order forms are first pre-processed, generating one or more individual orders for each supplier. The order number on the job details dialog box is used to uniquely identify each order form.

Note the [Add/Edit] report button as per the Tools > More > Edit User Templates dialog so that reports can be created and edited as an inline process to reporting.

Add Item

This allows the operator to add a material item from any category in the material database. Select the material category, then select the required item to be added to the material list for this job only. The added items do not relate to the roof geometry at all.

Add Other

This adds a new field to the end of the list allowing you to enter any information into the Category, Supplier and Description fields. This has replaces the User fields seen in previous versions. This is used to add such things that are required on a job that cannot be quantified as a function of the roof geometry, such as site clean up, crane hire etc.

Tile-Waste

This button displays the tile waste summary dialog box. Here you can modify specific tile waste factors for the current job. This only applies to tile roofs.

When you click “Calculate”, the Gross Qty is updated with respect to the waste percentage value and the round up value. When you click “[OK]” the Gross Qty is transferred back into the Reporting dialog box.

Cancel You can cancel any changes you have made and close this dialog box

ExportCSV This allows you to write the table of information on this dialog box to a comma separated value file, ready to import into other computer systems

ExportGRIM This allows you to write the current job as a GRIM file. If you have given this job a quote number then the name of the grim file is <Quote Number>.GRO. If you have not, the name of the grim file is GrimFileOut.GRO.

You also get separate grim files defining the materials required from each supplier. These are named Order-<Job Number>-<Index>.GRO. The format of a GRIM file is dewcribed later in this manual and how the GRIM file is used in conjunction with external systems such as a business management system.

A plot file of the roof plan is also exported in HPGL format that may be used to illustrate reports in other systems. It is saved as GrimOutFile.plt into the …\User folder.

A TIFF bitmap image file is also created. If a job number exists, then the file is called Job#.TIF. If no job number is defined, then it is called GRIMOUTFILE.TIF.

Set-Suppliers

This allows you to set the supplier for each material line item. When you click this button, the following dialog is displayed.

On this dialog, you see the supplier for each material line item. By default, the initial supplier name is the same as the supplier. To change the supplier you can either click the Set-Supplier button or click the ‘…’ to the right of each line item. If you click the Set-Supplier button, you can set a range of line items to affect.

Set-Finishes

This command lets you set the finish for any or all the material line items. It operates in a similar fashion to then Set-Suppliers command.

Set-Discount This button will let you set the discount for all line items.

Next-page This will display the next page, if there is one.

Prev-page This will display the previous page if there is one.

[OK] This lets you close the dialog box.

List Existing Quotes

Each time you select Supply-Only, or Supply and Install the software wants to re-calculate the quotation with the latest details and prices.

If you have already saved a quote using the Save button, when you select Supply-Only you are presented with a list of quotes in the job similar to the list box to the right.

Here you can select an existing saved quote, or select ***Re-Calculate quote *** to recalculate the quote with the latest values.

This also applies to the Supply&Install, Nett-Only and Fascia&Gutter Reporting commands.

Quote Register

The software automatically creates a register of all quotes completed, in the order they are completed. This makes it easy for the operator to go back to a previously saved quotation. In the process, the job database and model are opened and displayed on screen.

The Quotation Register is saved in a CSV (Comma Separated Values text file) format which allows the register to be used by other software such as Microsoft Excel or a business management system. The file name is QuoteRegister.CSV.

The file is in the form as shown below:

Quote Name,Database,Model,Date,Time, ... Q101-12May09-Tiles,BennetBldrs,34HighSt,29-May-09,14:29:03, Q102-12May09-Tiles,BennetBldrs,34HighSt,29 May 2009,14:29:48, Q103-12May09-Tiles,BennetBldrs,34HighSt,29 May 2009,14:30:47, Q103a-12May09-Tiles,BennetBldrs,34HighSt,29 May 2009,14:30:47, Q103b-12May09-Tiles,BennetBldrs,34HighSt,29 May 2009,14:30:47, Q104-12May09-Tiles,BennetBldrs,34HighSt,29 May 2009,14:31:50, ... Etc

The Quote Name is extracted from the name given to the quotation when it is saved from the Nett Only, Supply-Only or Supply+Install screen dilaogs. The list is continuously created until the data is deleted.

Some situations may require more data to be saved with the quotation list. For example, in addition to the Quote name, Database name, Model name, date and time, you might need the job cost total. To achieve this you must create a template (similar to creating a GRIM file template – refer description in Section 6 of this manual) that adds the extra information.

The template uses key text strings, as used when setting up your report templates, in the order that the data is to appear in the list. One small difference to how it is used in templates is the need to include .DAB to the end of the ###DatabaseFileName string. You create the text file using a text editor such as Notepad and the file must be called QuoteRegister.GRT (GRT as in GRIM Template). Let’s add the job total price to our Quotation Register and the first line of the file would look like this:

###QuoteName,###DatabaseFileName.DAB,###DatabaseModelName,###Today,###Time,Job Total is: $###JobTotal

This has the effect of adding the text, Job Total is: $. Then the key text string adds the dollar amount. When the Quote Register is created, and subsequently added to, the extra information is also added.

In our example, a section of the Register would now look like this:

Quote Name,Database,Model,Date,Time, ... Q101-12May09-Tiles,BennetBldrs,34HighSt,29-May-09,14:29:03,Job Total is: $158.69 Q102-12May09-Tiles,BennetBldrs,34HighSt,29 May 2009,14:29:48,Job Total is: $168.12 Q103-12May09-Tiles,BennetBldrs,34HighSt,29 May 2009,14:30:47,Job Total is: $258.34 Q103a-12May09-Tiles,BennetBldrs,34HighSt,29 May 2009,14:30:47,Job Total is: $245.36 Q103b-12May09-Tiles,BennetBldrs,34HighSt,29 May 2009,14:30:47,Job Total is: $228.34 Q104-12May09-Tiles,BennetBldrs,34HighSt,29 May 2009,14:31:50,Job Total is: $162.69 ... Etc

The extra text, Job Total is: $ and the dollar value added. This set up of the QuoteRegister template can be set up to be as complex or as simple as required for providing the information you need to help run your business.

Headings for each column of cells that you define, in addition to the Date, Time etc, must be manually inserted in to the CSV file the Job Total is: $ for example. The heading would then read:

Quote Name,Database,Model,Date,Time,Job Total is: $

Recalling Jobs from the Quote Register

When going back to a job, the operator has the option of simply opening the Database and Model, or you may use File > Open Quote. This presents the full list in the Quote Register in chronological order. Select the quotation you wish to open and the software opens the right Database and Model and then accesses the quotation.

Modify Quote Total

This option allows the operator to modify the final total quotation price for the job and will be saved with the quotation.

Select the [=] button and a box is displayed that displays the job total price calculated by the software based on all materials (and labour) for that job. This may be adjusted up or down, and the new job selling price inserted. This new value is displayed in the Job Total (ex tax) and a new line item displayed which is the value of the adjustment to the job total, up or down.

This is described as a rebate or extra and is saved as a Key Text called ###Rebate (refer Appendix). Such variations to a customer’s quotation can then be displayed on the office or sales person’s copy of the quotation by adding the Key-Text String to the office copy template.

Left click in the field that you wish to modify, in this case the Job Total, change the amount to that required and the adjustment will be shown in the Rebate/Extra field, as shown below.

A negative number is a rebate or discount, a positive number is an extra or additional amount.

The Rebate/Extra is a random adjustment that is made by the estimator at the late stage of closing off a job and making the call to round up or down a quote. If you add an amount to say, round the quote up from $14,797.00 to $15,000.00 then that is an adjustment up (Extra) or if you round it down to $14,000.00 then that is a Rebate. The difference is the amount that gets applied to the Quote Groups if enabled when Quote Groups are set up [Add in Pro-Rata % for Extra/Rebate – Y/N]. It does this so that the Quote Group sub-totals make sense – that is, the adjustment amount is pro-rated back across the respective Quote Groups items. If you had, for instance, 5 quote groups and the rebate total for each one was $100 (unlikely, but stay with me), then providing a rebate of $500 would subtract $100 from each of the Quote-Group Totals. This is done to allow the Quote Groups total to sum to the total of the Supply & Install dialog, after the rebate/extra has been applied.

Sales tax is applied if defined in System Preferences and the Total (including tax if applicable) is displayed and this is the amount printed on the customer’s quotation.

An additional line under Material Items shows the calculation of the material cost based on a square metre (or square foot) rate determined by the material cost divided by the roof area. This is handy as a cross check of the job cost to ensure that you haven’t made any significant error in your quotation. A similar line exists for Labour when you do a Supply and Install costing.

Job-Info and Options

The [Job-Info} button on the Supply-Only dialog allows you to change details about the Job, Customer, Installer etc without having to back up out of this dialog and have it recalculate the costings.

The [Options] button takes you directly to the Preference Settings that relate to the job costing dialog screen without having to back up out of this dialog and have to recalculate all the values.

![]()

Note: This is only saved with the current estimate if you select [Save]. If you quit the Supply+Install dialog without saving, these changes are lost.

Reporting > Supply+Install

When you click Reporting > Supply+Install, all the materials are tallied, sorted and displayed on the Materials dialog box as well as the installation charge displayed on the Labour sub-total dialog.

The reporting for the job takes account of stages defined using Stage Manager such as first storey, second storey or roof material and trim. Please refer to the detailed description of Stage Manager to know how this is applied.

The title on the dialog box describes the name of the current quote as well as what page is displayed.

This dialog is similar to that for Supply-Only, except you can alter the labour charges as well as assign markup percentages to the labour and material charges. Only the differences between the two costing systems are discussed here, so please read the previous section, Supply Only.

Any line item displayed in the Supply and Install list can be modified by double clicking the line item. The description can be changed and a calculation can be typed into the field.

Labour Subtotal

Clicking the Labour Sub-total displays the Roofing labour charges dialog box for this job.

For each item, there is a quantity, a rate and the total. The labour total is then the sum of the individual totals. Most of the items and rates are derived directly from the Reporting labour-rates dialog box plus those items defined in Extras.csv.

For details of Extra items, refer to Set-Up > More… > Extras.

The value labelled User lengths, is derived from the Cover > Flashing > User-Lens command.

![]()

Note: If you need a pay rate that takes account of pitch use Tiler’s Pay where you can define multiple pitch intervals.

The quantities on this dialog box are either NETT or GROSS depending on what you set on the Set Up > Metal-Rates dialog box.

In the Roofing labour charges dialog box you can alter the quantities and rates. Those changes you make will only effect the current job.

Labour markup This is the labour mark-up percentage.

Labour total This is the labour total amount including the labour mark-up percentage.

Material subtotal This is the sum of the material costs.

Material markup This is the material mark-up percentage.

Material total This is the material total amount including the material mark-up percentage.

Job total This is the total cost for the job including material and labour.

Modify Quote Total This option allows the operator to modify the final total quotation price for the job and will be saved with the quotation.

In addition, we have also provided totals for each line item to the right, and a cost per unit area option for both Materials and Labour, to assist our customers to understand their estimating pricing against the roof and wall areas.

The job total price calculated by the software based on all materials (and labour) for that job. This may be adjusted up or down, simply double click inside the price cell, and the new job selling price inserted. This new value is displayed in the Job Total (ex tax) and a Rebate/Extra value is displayed which is the value of the adjustment to the job total, up or down.

This is described as a rebate or extra and is saved as a Key Text called ###Rebate. Such variations to a customer’s quotation can then be displayed on the office or sales person’s copy of the quotation by adding the Key-Text String to the office copy template.

Left click in the field that you wish to modify, in this case the Job Total, change the amount to that required and the adjustment will be shown in the Rebate/Extra field, as shown below.

A negative number is a rebate or discount, a positive number is an extra or additional amount. Sales tax is applied if defined in System Preferences and the Total (including tax if applicable) is displayed and this is the amount printed on the customer’s quotation.

Fascia-Gutter

Fascia-Gutter

When you click Fascia-Gutter, the following dialog box is displayed.

This reporting method simply displays the materials for fascia and gutter and provides a quick quotation method for fascia and gutter only jobs. All too often valley material is also required, so it is included. The process for generating a quote and producing reports is the same as the other reporting methods. By design, the rate for the gutter material in this example is set to zero.

Nett-Only

Nett-Only

When you click Nett-Only, the following dialog box is displayed.

This Reporting process gives you access to a Reporting method based on price per unit area of roof and per unit length of line category. (You set the base prices using Set-Up > Set Up Pay Rates > Nett-rates). The pricing method simply reports a fixed set of line items (roof and trim) and uses the geometric (nett) values as the quantity. So if you quote by price then simply model the roof and go to the Reporting option. You do not need to select the specific roof cover material or define flashings, battens etc as your pricing would typically include any variations.

As you can see, you have the same facilities as on the Reporting Supply-Install dialog box.

If you wish, you can select a line item, and insert your own description for each and every line item. These changes relate to this quotation only. Don’t forget to select the Save button when you’re finished preparing the quotation so that the same details can be recovered later.

Bill of Quantities

A useful feature of the Nett-Only quote is that you can also do a quote on the nett areas of the roof without having to draw it up. If you have been given all the quantities of the roof you can simply enter them into the Quantity field, and click Re-Calc, the material side of the job will then be costed for you. This is particularly useful when you have been given a Bill of Quantities from the local Quantity Surveyor with no roof measurement details. This is process seems prevalent in the UK market where many jobs are supplied as a Bill of Quantities only, for whole or part of the roof job.

Select the [Options] button and you will be asked if you wish to display zero quantity items. In this case you would of course, so that you can add the numbers that you need for the job.

Double click a cell in any line item and change the value in it.

If you need to do labour as well as materials, simply click on the Copy Quantities to Labour Items >> button and all the quantities that you have entered into the material fields will automatically be copied into the corresponding labour fields. You will still need to click on the Labour Subtotal button to ensure that the labour is calculated.

These functions may be used in conjunction with QuoteGroups to produce custom quotations often required when responding to requests for quotations from a Quantity Surveyor who supplies you with the quantities to be used and you supply the costings for your company to deliver the goods and services.

Drawings

Drawings

When you click Drawings, you can now print up to 8 different standard CAD drawings or any number of drawings saved as Microsoft Word or Excel Templates. Refer to the process description for creating these at the end of this section of the manual.

The Select Drawings to print dialog box is displayed from which you select the drawings you want.

| Drawing Name | Template Name | Intended Use |

| Roof drawing | Drawing-Roof | Shows the roof |

| Batten drawing | Drawing-Batten | Shows the battens on the roof |

| Block layout | Drawing-block | Shows the blocks on the roof as created by Auto-Block |

| Off-cut layout | Drawing-off-cut | Shows the cuts and off-cuts created by Gen-Off-cuts |

| Off-cut layout(Colour) | Drawing-Off-cut-Colour | Shows a colour coded printout of the Off-cut Layout |

| Panel layout | Drawing-sheet | Shows the sheets on the roof as created by Gen-Sheets |

| Panel sequence | Drawing-Sheet-Sequence | Shows the sequencing of panel cutting derived from Linear Nesting |

| Panel cutting details | Drawing-Sheet-Cutting | Shows the detailed dimensioned panels |

| Flashing drawing | Drawing-flashing | Shows the roof and dimensions for each roof line as detailed by Dimension-Roof Lengths |

| Flashing profiles | Drawing-Flashing-profiles | Details the workshop drawings for the fabrication of custom flashings. The standard template has four profiles displayed with the following fabrication details for each new profile, and the cutting list of required lengths for the job. A new page is automatically created for each new group of up to four profiles. |

| Single-Ply Layout | A4-Form | Shows the membrane layout generated by Cover > Select-Membrane > Layout-SinglePly |

| Wall Plan | Drawing-Wall-Plan | Shows a plan view of your wall outline |

| Wall Elevations | Drawing-Wall-Elevation | Shows you the elevations of each wall outline |

| Arc Roof Production Drgs | Found under Cranking.DAB | Details the workshop drawings for the fabrication of curved roofing |

| 3D Design Drawing | Drawing-3D | Shows the roof in a 3D view |

| Scaled Ruler | No template | Creates a scaled ruler with any odd-ball scale which allows random measurements to be taken from a copy of a plan. |

Once you click [OK], the particular drawings you want to print are first prepared for printing and then sent to your printer.

Section Reports

Several additional report options are available that allow for the ability to create individual metal cutting list reports per roof plane.

The standard Sheet Cutting List Summary is created looking at the entire roof and putting short panels together to meet the Min Length setting when turned on in your panel allowances.

However, the Section Report is an entirely separate process and looks at each roof plane individually, and puts short panels together to meet the Min Length setting one roof plane at a time. So one cutting list may not be the same as the other, because the short panels are not nested in the same way or at the same time.

You cannot mix and match them – they are two distinctly separate outputs and most times, will not parallel each other and may indeed cause confusion for you and your customers.

The positive aspect of this is that, in general, the total length of coil for the job stays the same, regardless of the method used to generate the cutting list output – except when a single 10” piece becomes a single 4’1’ piece for example (if your min length is set to 4’1″) which does add a few extra inches or millimetres to the panel lengths for Section Report because it is not agregated over the whole roof, but one roof plane at a time.

To prepare for a “Section Report” as we have named them, the user must define various areas of the roof as sections (typically “A”, “B” etc.) and then number individual roof planes within each section using the Set-Section function under Estimate > Set-Panels.

You use the Set-Sequence button to change the order of the plane areas to suit your method of working – typically from longest roof panels to shortest.

Once this is complete, a Section Report can be produced by simply utilising the ###SectionReport, ###SectionReport2 or ###SectionReport3 key text strings in your report template which will result in a report similar to that shown below with the plane area and the cutting list for that plane.

###SectionReport

###SectionReport provides a layout of each roof plane in turn, and includes waste and plane area in the corresponding cutting list table for each plane area of the model.

###SectionReport2

###SectionReport2 provides a cutting list table for each plane area of the model and includes waste and plane area, without the graphical depiction of the roof plane area.

###SectionReport3

Removes the plane annotation numbers from plane imagery, as well as using double columns, losing Waste and Total Area per panel in the process over ###SectionReport.

Below is a closer look at the two column format of the SectionReport3.

Typically associated with the full blown commercial mode reports are the Flashing Table which includes the angle of bend for each piece of trim. The angle of bend is calculated automatically by the software from the roof geometry. It uses the pitch of the roof and the angle made between adjacent roof planes.

New “section-style” tables have been created for users who want an abridged version of the current report table capability, but with a focus on ensuring all information is contained for manufacturing purposes. The two new key text strings are ###SectionStyleTable and ###WallSectionStyleTable and output panel cutting lists for metal panels on both roof and wall estimations.

###FlashingTable

Available for commercial roofing to display bend angle of flashing, the number of pieces of each length and the product code:

###FlashAccesstable

Available for commercial roofing to display accessories and fasteners associated with all the trim and panels in that job:

###ExtrasTable

Displays any Extra items selected for the current estimate.

Wall and Roof Facet Reports

Additional capability is available to display roof and wall models in isometric view and provide summaries of areas, pitches, lengths etc.

###ROOFFACETTABLE

Produces a table of roof facets, labelled with A, B, C etc. and a companion table of facet letter, area and pitch.

###ROOFFACETTABLE2

Produces a table of roof facets, labelled with A, B, C etc. and a companion table of facet letter, area and pitch and plane type (material).

###ROOFFACETTABLE3

Produces a table of roof facets, labelled with A, B, C etc. and a companion table of facet letter, area and pitch and plane type (material) and azimuth.

###WALLFACETTABLE

Produces a table of wall facets only, labelled with A, B, C etc. and a companion table of facet letter, area and plane type. (see example below)

###WALLFACETTABLE2

Produces a table of wall facets with windows and doors, labelled with A, B, C etc. and a companion table of facet letter, area and plane type.

###WALLFACETTABLE3

Produces a table of windows and doors only, labelled with A, B, C etc. and a companion table of facet letter, area and plane type.

To get the most from this simply requires trial and error and clever layout and design of your templates.

Pay Rates

Set up > Pay Rates takes you to the Labour setup commands – specifically,

Tilers’ pay rates – fixed Allows you to setup fixed tile rates.

Tilers’ pay rates – variable Allows you to setup variable tile rates – with increments for storey and pitch interval.

Tile waste factors Allows you to setup tile waste factors.

Metal pay rates – fixed Allows you to setup fixed metal rates.

Metal pay rates – variable Allows you to setup variable metal rates – with increments for storey and pitch interval.

Curved metal pay rates Allows you to setup curved metal installation rates.

Nett pay rates Allows you to setup nett pay rates ie nett cost/m².

Quote Groups Allows you to setup Quote Groups.

Wall cladding pay rates Allows you to setup Wall cladding installation rates.

The functions for pay rates may also be selected from the Reporting Icon menu for ease of use. This allows you to quickly jump back and change a lbour rate while still in the Reporting stage.

Tilers’ Pay Rates

Tilers’ Pay Rates – Fixed

This command displays the Roof Costing-Rates dialog box allowing you to set or change various quote rates and job cost rates associated with the estimate on a per square basis or per unit length. There is one rate regardless of pitch of the roof or storey number. The items are described below:

Hip cover length This value determines the number of hip tiles required. It is independent of the tile you selected.

Note that it is not used if you have supplied a hip tile length when you defined the tile using Set-Up > Tile.

Underlay/Sarking roll size This value determines the number of rolls of underlay.

Cartage per 100 tiles This value determines the total delivery cost.

Underlay/Sarking quote rate This is the rate to quote underlay/sarking.

Fall protection quote This is the rate to quote fall protection.

Default no of units This is the default number of housing units for this job.

Batten 50×25 quote This is the rate to quote 50×25 battens.

Batten 50×38 quote This is the rate to quote 50×38 battens.

Batten 50×50 quote This is the rate to quote 50×50 battens.

Batten 75×50 quote This is the rate to quote 75×50 battens.

Batten User quote This is the rate to quote the user defined batten.

Ridge cover length This value determines the number of ridge tiles required. It is independent of the tile you selected.

Note that it is not used if you have supplied a ridge tile length when you defined the tile using Material > Tiles.

Batten length This is the length of battens per m2 of roof. It is used if you perform the estimate using the area method.

Underlay/Sarking cost rate This is the cost of the underlay/sarking.

Fall protection cost This is the cost of the fall protection.

2nd storey excess An extra value for second storey work.

Installers percentage The extra percentage to apply to the installers pay.

Batten 50×25 quote This is the cost of 50×25 battens.

Batten 50×38 quote This is the cost of 50×38 battens.

Batten 50×50 quote This is the cost of 50×50 battens.

Batten 75×50 quote This is the cost of 75×50 battens.

Batten User quote This is the cost of the user defined batten.

Waste per course The number of tiles you want to add per course if using the coursing method.

Waste – area method The number of extra pieces you want based on the total length of hips and valleys.

Sealant The rate per metre to add sealant to the trim. You define the finish of the ridges, gables and valleys etc as “Seal” to get a sealant value added to the Reporting dialog box.

Flexible pointing The rate per metre for flexible pointing.

![]()

Note: The cartage per 100 tiles variable described above will not appear in the Supply and Install dialog if the value is set to 0. If a value is included, then it will appear and the value determined by the number of tiles ordered. If a value is set, then it will appear in the material list summary, even if you have not estimated for tile. This will be added to the material list even if a value is also set for delivery under Areas – refer to Set-Up > Areas.

Tilers’ Pay Rates – Variable

Tilers’ Pay Rates – Variable

This command lets you define tile installer pay schedules based on storey, line-item and user defined pitch interval. This Pay Rate may be applied to either Tiles or Tiles+ databases. You may define as many Tile-Pay rates as you need – for example, union or non-union rates; or sub-contractor A and sub-contractor B rates. Just remember, the more rates you set up the more you have to maintain if rates change, as they inevitably do.

Name This is the name by which you select this pay rate in future.

Roof Unit The basis on which the costs are applied and the multiplier.

Storey This is the storey to which these values relate. You can have up to 10 storeys for the one pay rate.

Pitch intervals These values reflect those you set with the Intervals button at the foot of the dialog box. For each pitch interval value, you get a column of numbers associated with a line item. To edit a line item, highlight that column by clicking the pitch interval label.

Roof / sqm (sqFt) This is the installers rate to lay tiles on the roof.

…. The rest of the line items relate to hip, valley, gable and barge finishes you select under Cover > Select-tile.

Select This allows you to select an existing pay rate schedule.

Delete This allows you to delete an existing pay rate schedule.

Add This allows you to add a new pay rate schedule.

Update This allows you to update an existing pay rate schedule.

Auto-Fill Interval Automatically fills the table with the loading for each pitch interval.

Auto-Fill Storey Automatically fills the table with the loading for each storey.

Once the pricing table has the appropriate rates for each job function completely filled in, and don’t forget to do each storey, the file is saved away in the system using the “Add” button. Standard pricing files are stored within the software structure however user-defined pricing files are stored in a <filename>.DPT file format. In our example we created a labour pay rate file called “Interlocking Concrete Tiles” so this will be saved as InterlockingConcreteTiles.DPT.

Once the pricing table has the appropriate rates for each job function completely filled in, and don’t forget to do each storey, the file is saved away in the system using the “Add” button. Standard pricing files are stored within the software structure however user-defined pricing files are stored in a <filename>.DPT file format. In our example we created a labour pay rate file called “Interlocking Concrete Tiles” so this will be saved as InterlockingConcreteTiles.DPT.

The <filename>.DPT file is saved in a text file which allows you to make changes in an external program such as Notepad or Wordpad, or indeed, a spreadsheet program such as Excel. This is useful if you have major changes to pricing across the board and changing the values in columns is a whole lot easier in Excel if you know how. For the rest of us, open the pricing file in AppliCad (Costing > Tile-Pay) and do it long hand, one item at a time. Once complete don’t forget to select “Update” and the changes will be saved.

Interval Labels

Customers utilising the GRIM output feature of AppliCad to link the estimation process to downstream systems have often had to create duplicate mappings of labour rates due to the output of variable labour rates in the Roof Wizard software. Outputs such as Ridge (1, 22.5) where the 1 specifies the storey and 22.5 specifies the pitch have had to create multiple mappings for each pitch gradient in 0.1 degree increments. In 8.2, we have provided the ability for each pitch interval to be given as a label (e.g. A, B, C as can be seen in the attached image) with the output therefore being Ridge (1,A), or Ridge (1,B) etc. This greatly reduced the number of mappings required, thus reducing the workload for our users and speeding up the interface between systems.

Labour Item Decriptions

Also available is the ability to define the Labour item descriptions. These definitions are stored in a text file called LabourFile.dat and may be created or edited in a text editor such as Notepad or Wordpad.

The quick way to create the user defined group description file is to copy the file “LabourFile.TMP” to “LabourFile.DAT” in Windows Explorer, and then make any modifications using a Windows-based text editor such as NotePad or WordPad. Only attempt to edit this file if you are proficient in the use of the editor program. To return to standard groupings, the user must remove the file “LabourFile.DAT” so that the “LabourFile.TMP” in the user directory is found instead. You might also open LabourFile.TMP in the editor and use File | Save-As to create the LabourFile.DAT with your new descriptions and charges.

This will handle every permutation of Reporting for your tile item installation options.

The format of the LabourFile.dat:

#Tile Labour File #Line above must remain in file for it to be located by software #Format 0=Header, 1=Main Cost, 2=Add Cost > Group Description > Reporting Calculation Method 1=Area, 2=Len |Group - see below #1 = Field Tiles, 2 = Ridge, 3 = Hip, 4 = Valley, 5 = Verge, 6 = Eaves, 7 = Abutments, 8 = Aprons, 9 = Box Gutters, 10 = Battens, 11 = Counter Battens, 12 = Insulation, 13 = Sarking/Underlay, 14 = Fall Protection, 15 = Downpipes, 20 = Extras #Last option defines whether default is to include in Pricing or not 0=No, 1=Yes 0|AREA|0|1|0 1|Field Tiles|1|1|1 2|Extra Over for Nailing Coverings Twice|1|1|0 2|Extra Over for Clipping Coverings in Lieu of Nails|1|1|0 2|Extra Over for Clipping Coverings plus Nailing|1|1|0 0|RIDGE|0|2|0 1|Mortar Bed & Mechanically Fix All End|2|2|1 1|Two Ridge Dry Ridge System|2|2|0 2|Dentil Slips|2|2|0 2|Extra Over Mechanically Fix All Ridge|2|2|0 0|HIP|0|3|0 1|Mortar Bed & Mechanically Fix All End|2|3|1 1|Two Hip Dry Hip System|2|3|0 2|Dentil Slips|2|3|0 2|Extra Over Mechanically Fix All Hip|2|3|0 2|Arris/Bonnett Hip|2|3|0 2|Mitred Hip|2|3|0……………….etc

Below is a screen shot of the file we created for the demonstrating the function. Notice the header of the file shows the order in which the information must be input. Once setup, you have total control over the descriptions you use for each labour item. This includes whether the labour relates to Field tile, ridge or hip etc, the description and the cost per area or per length.

The “LabourFile.DAT” file has the following format, as outlined in the header of the file:

# = Comment Line A|B|C|D|E = Data Line, where: A 0 = Header Line 1 = Main Cost 2 = Additional Cost B Line Item Description C 1 = Item to be priced by Area 2 = Item to be priced by Length D 1 = Field Tile Catgeory 2 = Ridge Tile Category 3 = and so on, see documentation E 0 = Do Not include in pricing calcs by default 1 = Include in pricing calcs by default.

Screen captured from the LabourFile.dat being edited in Windows Notepad

The pay rate is selected when the tile is selected to cover the roof under the Cover > Tiles command.

For the Tiles+ database select it here:

The selected tile details dialog for Tiles+ data file.

Click the down arrow for a drop down list of available pay scales that you have defined.

![]() Note: Should the pay rate be changed for any reason after you have selected it, then you must reselect the rate. Indeed, this applies to any database of materials or Reporting – if it is changed, you must re-select it and re-calculate the costing.

Note: Should the pay rate be changed for any reason after you have selected it, then you must reselect the rate. Indeed, this applies to any database of materials or Reporting – if it is changed, you must re-select it and re-calculate the costing.

Remember: After creating a new labour file, test it on a simple job to ensure the descriptions are transposed correctly. If it works correctly, then you are ready to use it on real jobs. This is a good tip whenever you change or update a data file, whether a labour or material data file.

For the Tiles database, select the pay rate here:

The selected tile details dialog for Tiles data file.

![]() Note: Should the pay rate be changed for any reason after you have selected it, then you must reselect the rate. Indeed, this applies to any database of materials or Reporting – if it is changed, you must re-select it and re-calculate the costing.

Note: Should the pay rate be changed for any reason after you have selected it, then you must reselect the rate. Indeed, this applies to any database of materials or Reporting – if it is changed, you must re-select it and re-calculate the costing.

Tile-Waste

This command displays the Tile-Waste dialog box allowing you to set or change the wastage factors for different tile items.

The tile wastage values are calculated in the following sequence:

The nett number of field tiles is first calculated,

Then the number of extra pieces per course is added,

Then the extra number of field pieces per length of hips and valleys is added (field pieces per metre or per foot of hip and valley),

Then the percentage waste of field pieces is added,

Then the total number of field pieces rounded to give the final number.

Each waste value is applied in turn. If you do not want a particular waste factor to be applied then set the value to zero.

The first option – Extra Field Pieces (per course) is a number or decimal fraction, of a tile to add at the end of each course line to account for waste as a result of typical job variables such as breakages. The more course lines, the more field pieces that are added to the total tile count.

Extra Field Pieces (per length of hip and valley) is applied as a result of the total length of hip and valley combined and expressed as pieces or decimal fraction of pieces, per metre (or foot) of hip and valley. This is typically used to account for extra tiles that may be required as a result of breakages during cutting of tiles to fit at hips and valleys.

The more cuts there are, often the more breakages there are. No account is made for the re-use of the off-cut, as is sometimes possible with metal tiles.

If the off-cut is reused as a matter of course, then this needs to be taken into account and the number reduced. Experiment with different values until you get the correct result based on your experience.

All other fields are individual values for each category of tile piece. Waste % takes the total number calculated based on the course lines and adds the specified percentage and then rounds up to the nearest value as specified. A value of zero does not round up.

Multiple configurations of tile wastage and rounding of elements can be specified and saved into various configuration files. These files can now be linked to each tile record, thus allowing improved streamlining of waste and rounding calculation without requiring the estimator to remember to modfiy these values. Select [Save-As] to save the tile waste file and select [Load] to load a previously defined set of values.

When you click [OK], the values are saved. These values are applied to the tile calculations when the Reporting > Supply+Install is selected. A summary of the tile waste calculations is then displayed when you select Tile-Waste from the Supply+Install or Supply-Only dialog box.

Metal Pay Rates

Metal Pay Rates – Fixed

This command displays the Roofing Labour rates dialog which allows you to set installation rates for different categories of roofing items on a per square basis or per unit length. There is one rate regardless of pitch of the roof or storey number. The following table describes the rates:

Labour Rate |

Description |

Straight roofing per m2 |

The rate to install straight sheeting on the roof (or verandah) |

Insulation per m2 |

The rate to lay the insulation |

Ridges/hips per m |

The rate to install the ridges and hips |

Valley per m |

The rate to install valley flashing |

Fascia only per m |

The rate to install fascia flashing only |

Gutter only per m |

The rate to install gutter only |

Fascia barge per m |

The rate to install fascia on a barge |

Fascia and gutter per m |

The rate to install fascia and gutter together |

Barge per m |

The rate to install barge flashing |

Apron per m |

The rate to install apron flashing |

Batten per m |

The rate to install battens |

Each Downpipe |

The amount to install each downpipe |

Each chimney |

The rate to cater for each chimney |

Labor markup % |

The percentage the total labour cost will be marked up in the final costing |

Labour quantities |

This is either “NETT values” or “GROSS values”. Nett values are the geometric values of the roof. Gross values are the quantities of materials you order. Setting the method here will effect the quantity you see in the Reporting dialog boxes later. They only apply to metal eoofing and metal flashing quantities for all methods of labour calculation – fixed and variable. |

Siding per sqm |

The rate to install siding per square metre |

Wall top per m |

The rate to install wall top flashing |

External corner per m |

The rate to install external corner flashing |

Internal corner per m |

The rate to install Internal corner flashing |

Door head per m |

The rate to install door head flashing |

Door edge per m |

The rate to install door edge flashing |

Box gutter per m |

The rate to install box gutter |

Curved roofing per m2 |

The rate to install the curved sheeting on the roof (or verandah) |

Each curved sheet |

The amount to add for each curved sheet |

Per curved apron |

The amount to add for each curved apron (bullnose verandahs) |

Per curved barge |

The amount to add for each curved barge (bullnose verandahs) |

Per curved hip |

The amount to add for each curved hip (bullnose verandahs) |

Per curved valley |

The amount to add for each curved valley (bullnose verandahs) |

Curved apron per m |

The rate to install curved apron (bullnose verandah) |

Curved barge per m |

The rate to install curved barge (bullnose verandah) |

Curved hip per m |

The rate to install curved hip (bullnose verandah) |

Curved valley per m |

The rate to install curved valley (bullnose verandah) |

Roof removal per m2 |

The rate for roof removal |

Gutter removal per m |

The rate for gutter removal |

Material markup % |

The rate to markup the material costs for the final quote |

Wall base per m |

The rate to install wall base flashing |

Window sill per m |

The rate to install window sill flashing |

Window head per m |

The rate to install window head flashing |

Window edge per m Wall Batten per m |

The rate to install window edge flashing The rate to install wall battens per metre |

After you make a change and click [OK], the changes are saved in rates.bin for use in all future jobs.

If you click the Pitch Allowance button the Pitch Allowances dialog box is displayed.

Here, you set the pitch ranges as well as the rate to apply for planes in that range. When you click Set Range, you can change the number of ranges. The maximum number of ranges you can have is 10.

These values are used in the labour charge calculation under Reporting > Supply+Install. Each plane in the model is tested for its pitch and area, and based on the roof pitch, the above table is used to derive a pitch allowance. The individual pitch allowances are added together to derive the total pitch allowance.

Metal Pay Rates – Variable

This command displays the Installer Pay Rates for Metal roofing box allowing you to set or change various labour rates associated with the installation of metal roofing. You select a pay-schedule for a job on the Cover > Select-metal dialog box. The maximum number of different labour rate tables is 50.

Name This is the name of this pay schedule.

Storey This is the storey to which the following rates apply. A schedule can have up to 10 storeys.

Pitch Intervals These are the pitch intervals you want to set for the job. You set them by clicking the Intervals button at the foot of the dialog. To edit a column of values you need to click on the interval value.

Line items For each line item you need to enter the rate per unit area or length for that line item. For roof removal and gutter removal only the first rate is actually read when the Reporting is performed.

Select This button lists up the existing schedules. You then select the one you want for editing. After selecting a schedule, the Update button appears letting you update the schedule.

Delete This button lets you delete the currently selected schedule.

Add This button lets you add the current schedule (schedules must have unique names).

Update Updates the currently selected table with changes.

Add-User Allows you to add any sort of labour charge that applies to walls. Each new item is given a unique index number. The example below shows a new rate for ‘Special Gutters’.

Delete User Allows you to delete a user defined charge. You will be prompted for the index number of the item to delete.

The example below shows a new rate for ‘Special Gutters’.

Del-User deletes the new rate.

Next/Previous Page These buttons allow you to toggle between the two available pages.

[Cancel] Closes the dialog box without saving the changes you have made.

Intervals Lets you define the pitch intervals you want to use – see below, Interval Labels.

[OK] Closes and saves the changes you have made.

User defined pay rate for Special Gutters

Interval Labels

Customers utilising the GRIM output feature of AppliCad to link the estimation process to downstream systems have often had to create duplicate mappings of labour rates due to the output of variable labour rates in the Roof Wizard software. Outputs such as Ridge (1, 22.5) where the 1 specifies the storey and 22.5 specifies the pitch have had to create multiple mappings for each pitch gradient in 0.1 degree increments. In 8.2, we have provided the ability for each pitch interval to be given as a label (e.g. A, B, C as can be seen in the attached image) with the output therefore being Ridge (1,A), or Ridge (1,B) etc. This greatly reduced the number of mappings required, thus reducing the workload for our users and speeding up the interface between systems.

When you click [OK], the rates you defined are saved for future use. You may set up as many different files as you have different pricing for different profiles or wall systems.

GRIM File Format

A GRIM (Generic Roof Interface Method) file is designed to facilitate the transfer of roof geometry and roof material costing data between AppliCad and other computer systems such as accounting and business management or ERP systems.

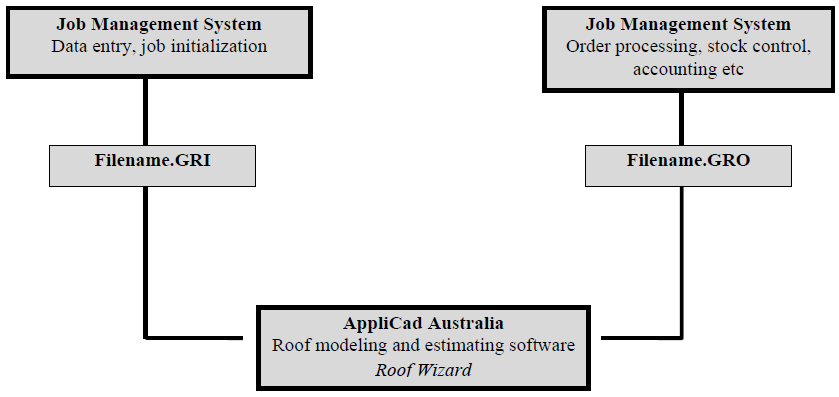

Brief overview of the Generic Roof Interface Method

The process assumes that a business wants to minimize data entry and/or re-use data across the enterprise that is entered already when a job is started. The job management system may be any number of proprietary management information systems that firms have to provide some degree of control over jobs, accounts, stock etc.

Creating the text file in GRIM format is simply a matter of writing a query in the job management system and saving the data in the appropriate form as described below. It can then be picked up by one of AppliCad’s programs (Roof X), either automatically or manually, and used without re-entering the data. AppliCad’s program models the roof geometry, automatically extracts roof details such as lengths, areas etc. and writes an output text file that may be picked up in a similar way and used by the job management system.

AppliCad’s programs do provide basic job management functions, but interfacing with advanced systems provides the tools to manage jobs at a much higher level. Typical users of this process will be medium to large roofing contractors and material suppliers that offer job lots for their clients.

The process marries up advanced job management and accounting with advanced roof modelling and take-off and closes the job management loop. Data may be created in the business’s management system and saved as a GRI file for pick up by the AppliCad application; it may also be saved from the AppliCad application for pick up by the business management system as described in the illustration below.

As it is possible that there will be much information that AppliCad creates that does not need to be shared with the business management system, a GRIM Template file can be created which filters the data exported. This delivers only the information that the business management system requires, in the order that it requires it.

The AppliCad Roof Wizard has been designed to not only model roofs but provide some job management and information sharing capabilities. The GRIM file is generated from the [Export GRIM] button on the Reporting > Supply and Install option.

A GRIM file is an ASCII file, with a header line followed by one or more lines containing a key text string and a value. A key text string is one of those defined for creating/modifying templates as described earlier in this manual.

A key text string starts in column 1 and is a maximum of 20 characters. The value for this key text string starts in column 21. For example, ###PITCH 26.6 where ###PITCH is the Key Text String and 26.6 is the pitch value.

The last line in the file is defined with ‘END’.

A sample GRIM Out File (GRO) appears below:

GRIM file header ###TODAY 16 July 1999 ###JOBDELAREA Area 1 ###JOBINSTALDATE 16 July 1999 ###JOBPICKUPDATE 16 July 1999 ###JOBDELDATE 16 July 1999 ###MAPREF ###COMPNAME AppliCad ###COMPADD1 70 Railway Road ###COMPADD2 Blackburn Vic 3130 ###COMPPHONE Ph 03 9878 5000 ###COMPFAX Fx 03 9878 5055 ###COMPACN ###COMPNOTE1 ###COMPNOTE2 ###SCALE 1 : 1 ###PAGE Page 1 of 1 ###PITCH 26.6 ###EAVEOFFSET 610 ###EAVEHEIGHT 2700 ###RAFTERSPACE 610 ###BATTENSZ 90x38 ###HIPTYPE 0 ###RIDGETYPE 0 ###VALLEYTYPE 0 . . . . . . . . . . . . ###TILEMAN ###TILECOLOUR ###TILEPROFILE ###TILETYPE ##TILEMATERIAL ###TILECOV 10.50 ###TILEBARGECOST 0.00 ###ROOFMAT Not included ###RIDGEMAT Roll top ridge, Merino ###FASCIAMAT Metal fascia, Mountain Blue ###GUTTERMAT Not included ###BATMAT Not included ###VALLEYMAT Not included ###BARGEMAT Not included ###INSULMAT Not included ###CROOFMAT Not included ###DPMAT Not included ###DATABASENAME Roof Wizard File : aasample.dab Model : model ###DATABASEFILENAME aasample ##DATABASEMODELNAMEmodel ###ROOFAREA 314.48 ###RIDGELEN 15.50 ###HIPLEN 47.49 ###VALLEYLEN 13.83 ###FASCIALEN 75.88 ###GUTTERLEN 75.88 ###BARGELEN 0.00 ###FASCIABARGELEN 0.00 ###APRONLEN 0.00 ###BOXGUTTERLEN 0.00 ###SHELLENDS 6 ###APEXES 4 END

Refer to the complete list of key text strings described here.

Repeated Structures

There are also repeated structures which handle material line items reported in the job as well as cutting list. For each material line item present in the job there is the following set of key text strings

LINEITEM the name of the line item:

###LINEITEM_SUP the supplier of this item

###LINEITEM_MAN the supplier of this item

###LINEITEM_CODE the product code of this item

###LINEITEM_PRO the profile of this item (user defined)

###LINEITEM_FIN the finish of this item (user defined)

###LINEITEM_QTY the quantity of this item

###LINEITEM_RATE the cost per unit of this item

If the line item defines straight metal roofing or flashings, a cutting list may follow. The cutting list is of the repeated

form

CUTLIST_SIZES the number of cutting list sizes to follow:

###CUTLIST_QTY the number off of the following length

###CUTLIST_LENGTH the length required

Labour line items are also written in a repeated form:

###LABOUR_ITEM The name of this labour item

###LABOUR_QTY The labour quantity

###LABOUR_RATE The labour rate

The following file segment shows this format:

LINEITEM Ridge ###LINEITEM_SUP StramitIndustries ###LINEITEM_MAN StramitIndustries ###LINEITEM_CODE RTRVCTL-- ###LINEITEM_PRO Roll top ridge ###LINEITEM_FIN Merino ###LINEITEM_QTY 2.000000 ###LINEITEM_RATE 10.280000 ###CUTLIST_SIZES 6 ###CUTLIST_QTY 1 ###CUTLIST_LENGTH 3200 ###CUTLIST_QTY 4 ###CUTLIST_LENGTH 2950 ###CUTLIST_QTY 6 ###CUTLIST_LENGTH 2840 ###CUTLIST_QTY 4 ###CUTLIST_LENGTH 2800 ###CUTLIST_QTY 6 ###CUTLIST_LENGTH 2720 ###CUTLIST_QTY 2 ###CUTLIST_LENGTH 2300

A material cutting list similar to that shown above is written if the name of the line item is one of:

‘Straight roofing’,

‘Ridge’,

‘Valley’,

‘Fascia’,

‘Gutter’,

‘Barge’,

’Apron’, or

‘Batten’.

The GRIM-In Process

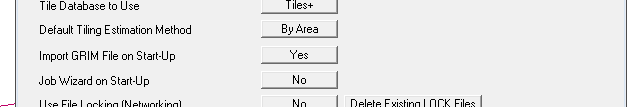

If the GRIM in process is to be used, the operator must tell the software that it should look for GRIM In files to be read at start-up. This is done by selecting the option through the Set-Up > Preference Settings > System Preferences dialog. Select the button, ‘Import GRIM File on Start-Up’ to toggle it to Yes.

At start-up the AppliCad software will look for any files with a *.GRI extension. The operator selects the required GRIM file and all data that has been set up at the business management software end will automatically populate the appropriate fields in AppliCad.

This minimises data entry and potential errors in transcribing information from the order form to the software.

The GRIM-Out Process

The GRIM out process is initiated from the Reporting > Supply Only or Reporting Supply and Install dialog box.

ExportGRIM This allows you to write the current job as a GRIM file. If you have given this job a quote number then the name of the grim file is <Quote Number>.GRO. If you have not, the name of the grim file is GrimFileOut.GRO.

You also get separate grim files defining the materials required from each supplier. These are named Order-<Job Number>-<Index>.GRO.

A plot file of the roof plan is also exported in HPGL format that may be used to illustrate reports in other systems. It is saved as GrimOutFile.plt into the …\User folder.

A TIFF bitmap image file is also created. If a job number exists, then the file is called Job#.TIF. If no job number is defined, then it is called GRIMOUTFILE.TIF.

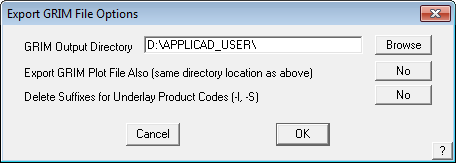

Selecting Export GRIM brings up the GRIM File Options:

Select the required path for the file. This may be a dedicated path where you have set up a utility program to look for newly created files for processing, thus automatically taking the GRIM data and processing it for use in an external program such as business management or inventory management software. The *.GRO file is written to the specified folder as described above.

Select [OK] and the following dialog is displayed. You may also set which quotes to output, if multiple have been created, and exclude zero quantity items if there are any.

Select the options you require and select [OK] to write the GRO file to the specified folder.

GRIM Roof Plan Picture (Plot File)

When you export a grim file, a plot file is created of the roof plan. The plot file is an ASCII vector format that conforms with Hewlett Packard Graphics Language 2 (HP-GL2) – this is a generic format used to drive Hewlett Packard plotters. Lines and line properties are plotted as defined by the operator using the Tools > Change Entity > Lines Styles option. Essentially what you see on screen is what will be plotted to the HPGL2 file. Sarking or Underlay planes (where there is partial Underlay) appear as filled planes.

The HPGL2 file format is an ASCII text file, which means the instructions may be viewed in a text editor and an importation routine may be easily written for custom applications where the roof plan needs to be displayed. Many word processors and graphics programs will import HPGL2 files directly. You may need to install specific functions to enable this feature.

A TIFF bitmap image file is also created. If a job number exists, then the file is called Job#.TIF. If no job number is defined, then it is called GRIMOUTFILE.TIF.

The TIF file output can be controlled using various options in the text file TIFFOPT.DAT so that the TIF images meets you subsequent use of the file – to illustrate the job in a database for example.

An example is shown here:

;xSize ySize xDPI yDPI 1200 700 150 150 ;Coursed (1=Yes, 0 = No) 0 ;Planes (1=Yes, 0 = No) 1 ;Black & White (1=Yes, 0 = No) 0

GRIM Template Files

This feature gives the user a method by which a user defined data file can be generated with specific data included as part of the output file, effectively working as a GRIM file filter. This would be most useful in transferring exactly the required data from Roof Wizard to other systems.

A Grim Template file is an ascii file with a ‘.grt’ extension. The file contains grim text strings which are swapped over for their current value when you do an ExportGRIM from the Reporting > Supply Only or Reporting > Supply and Install dialog box.

An example format data file would be something like the following:

My header line ###JOBNUMBER , ###JOBQUOTE ,###TAX, ###TOTALINCTAX This is some sample text

If you called this file MyGrim.grt, the result would be a file called MyGrim-data.csv with the actual values.

My header line jn-8888 , qn-9999 ,224.36, 2467.95 This is some sample text

You can have up to 5 grim template files in your user directory and up to 10 lines in the *.grt file.

Using the GRIM File with Pitch Intervals

Customers utilising the GRIM output feature of AppliCad to link the estimation process to downstream systems have often had to create duplicate mappings of labour rates due to the output of variable labour rates in the Roof Wizard software. Outputs such as Ridge (1, 22.5) where the 1 specifies the storey and 22.5 specifies the pitch have had to create multiple mappings for each pitch gradient in 0.1 degree increments.

Roof Wizard now provides the ability for each pitch interval to be given as a label (e.g. A, B, C as can be seen in the attached image) with the output therefore being Ridge (1,A), or Ridge (1,B) etc. This greatly reduced the number of mappings required, thus reducing the workload for our users and speeding up the interface between systems.

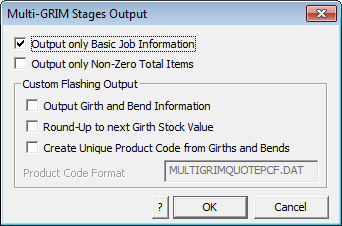

Multi-GRIM-Out

The Multi-GRIM option lets you generate a single GRIM file containing a breakdown of details based on each stage in your current job. You must have defined one or more stages using Stage Manager to continue with this command.

This command also works in a similar manner to Mutli-Grim Stages but will break down the details based on each Quote Group defined.

Multi-GRIM for Stages

(Pulldown Menu)

This command lets you generate a single GRIM file containing a breakdown of details based on each stage in your current job. You must have defined one or more stages to continue with this command.

The resultant gro file has each stage braced between a STARTSTAGE-ENDSTAGE pair. A sample file looks like this:

GRIM file header

STARTSTAGE

###STAGENAME Main roof

###STAGEINSTALLER Benny the builder

###STAGEINSTALLDATE 12 February 2001

###STAGEDELDATE 12 February 2001

###TIME 14:32:33

###TODAY 12 February 2001

…

ENDSTAGE

STARTSTAGE

…

ENDSTAGE

END

A plot file for each stage is also written. The format for the plot file is:

Order-<job number>-<supplier index>-<stage name>.PLT

Multi-GRIM for Quotes

(Pulldown Menu)

This command works in a similar manner to Mutli-Grim Stages but will break down the details based on each Quote Group defined.

Note that a feature is available to control what happens with Custom Profile Flashings where a product code is not normally allocated as each profile can be unique, based on different girth and/or number of bends. The GRIM file can be made to automatically create a product code using the girth and bends information.

![]()

Note: For the generation of the product code based on Girth and Bends there are a couple of things that MUST be checked and changed if necessary.

- The definition of the Flat Sheet for the fabrication of the Custom Profile – the Alternate Category must be left blank, or set to Fabrication (which is the default if left blank). Refer Help > Setup.

- You must have a MultiGrimQuotePCF.dat in the ..\User folder as described below. This sets the format of your Line Item product code to include the Girth and Number of Bends.

- You must also have a settings file in ..\User telling the software what file is used to define the format of the product code as referred to in #2. This file saves the settings of the dialog box and in particular the file name referred to in #2. This file must be called MultiGRIMQuote.dat. (The expectation is that the Dialog box is supposed to save this for you, but you need to check and if not there, put it there yourself using Notepad )

- Check that the supplier name used in the MultiGRIMQuotePCF.dat matches the actual supplier names used in the definition of your Flat-Stock.

You create a text file that controls the format of the product code for each Custom Profile, and the Supplier name must be the same name as used when you defined the Flat Stock. You may use spaces between each key text string item. The text file must be called MULTIGRIMQUOTEPCF.DAT and be in the form of:

Supplier1

###CODE-###BENDSx###GIRTH

Supplier2

###GIRTH x ###BENDS, ###CODE

This would result in a line in the GRIM file that might look like this:

Supplier1, CUSTOMType#1-5×300

….

And then the balance of the cutting list for this item called CUSTOMType#1, 5 bends and 300mm girth, the the details for the second supplier’s material order (if you have multiple suppliers of custom profile trim).

His order would look like this:

Supplier2, 300 x 5, CustomType#1

…..

And then the cutting list for this item.

Repeated as required for all Suppliers in the Flat Sheet product list.

Report Templates – Microsoft Word/Excel

Objective: To design or customize the report templates to suit your individual needs.

![]()

Note: This section may appear to be quite a daunting process at first as it requires use of many of the standard 3D CAD functions rarely used when modelling roofs and generating estimates. If also requires extensive knowledge in the use of MS Word and Excel, if they are to become your standrad report generators. We suggest you are very familiar with the workings of the respective software before returning back to this point.

There are two distinctly separate processes for creating report templates from AppliCad software. The CAD template (what we have used for 25 years and still support), and the seamless integration with MS Word or MS Excel for report generation.

When output reports are created by the software, it first looks for a Microsoft Word template of the required name form, for example QuotationLetter. The file it is looking for must be saved in the ..\User folder or ..\Corporate and must have the name of QuotationLetter.DOC without spaces as a Word Document or QuotationLetter.DOT as a regular Word Template document.

The file format must be Microsoft Office 1997 – 2003 compatible – that is, no XLTS or DOCX formats. This ensures backwards compatibility for all users.

If the software finds the DOC or DOT by the defined name, it will use it. If it does not find a Microsoft Word template, it will use the AppliCad default CAD template for QuotationLetter which is saved in the AppliCad database file, RoofWiz.dab. This will ensure that all your existing default CAD templates will work as they do now when the software is updated by new releases.

Creating a template in MS Word allows for more creativity in design and many operators may be more familiar with Microsoft Word than the CAD functions. The use of Word Templates is described later in this section. Using a Word template, you can have as much or as little information as you require for your projects. If you plan to use Word templates exclusively, you might consider going direstly to that section below, however, a lot of useful information is described in the CAD template section.

Setting Up MS Word/Excel as your Report Generator

This section describes the use of Microsoft Word/Excel to create templates. It is not a Microsoft Word/Excel tutorial – it assumes moderate to high level of competency in the use of Word/Excel.